Open arc self shielded wire for crack – free joining and build up applications

Applications:

Typical Mechanical Properties:

Tensiles Strength: 49 Kg/mm2

(70,000 psi)

Open arc self-shielded flux cored wire for high strength similar and dissimilar joining of low, medium carbon and low alloy steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 65 Kg/mm2

(92,000 psi)

Open arc self-shielded flux cored continuous wire for impact and compressive load applications

Applications :

Typical Mechanical Properties:

Hardness: 25 to 35 HRc (3 layer)

Open arc self-shielded flux cored wire with excellent resistance to impact and work hardening capability

Applications:

Typical Mechanical Properties:

Hardness:

As Deposited: 90 HRb (3 layer)

Work Hardened: 42 HRc (3 layer)

Open arc self shielded continuous wire designed to resist impact, galling and pressure

Applications:

Typical Mechanical Properties:

Tensile Strength: 55 Kg/mm2

(78,000 psi)

Open arc self-shield metal wed wire for hardfacing applications in construction and mining industries

Applications:

Typical Mechanical Properties:

Hardness: 50 – 58 HRc (3 layer)

Open arc self-shielded flux cored wire for severe wear by fine particle abrasion or erosion under moderate impact

Applications:

For wear protection of steel components in brick and tile, quarry and dredging industry :

Typical Mechanical Properties:

Hardness: 62 – 67 HRc (2 layer)

Open arc self-shielded Alloy wire containing niobium carbides for severe abrasive and erosive wear at elevated temperatures

Applications:

Typical Mechanical Properties:

Hardness: 60 – 68 HRc

Open arc self-shield flux cored wire with outstanding abrasive wear resistance even at elevated temperatures

Applications:

Typical Mechanical Properties:

Hardness: 58 – 64 HRc (3 layer)

Open arc self-shielded flux cored wire for wear-facing against abrasion and impact

Applications:

Typical Mechanical Properties:

Hardness: 52 – 58 HRc

Open arc self shielded continuous wire designed to withstand abrasion and moderate impact

Applications:

Typical Mechanical Properties:

Hardness: 50 – 60 HRc (3 layer)

Open arc self-shielded continuous wire for anti-spalling deposit with excellent cushioning, good impact resistance and high compressive strength

Applications:

Typical Mechanical Properties:

Hardness: 25 – 35 HRc (3 layer)

Open arc self-shield flux cored wire for joining and build up applications

Applications:

Typical Mechanical Properties:

Tensile Strength: 49 Kg/mm2

(69,000 psi)

Open arc self-shield continuous wire for build-up of table and roller liners

Applications:

Typical Mechanical Properties:

Hardness: 56 – 62 HRc

Open arc self-shield flux cored wire with excellent resistance to serve abrasion and erosion at elevated temperature

Applications:

Typical Mechanical Properties:

Hardness: 60 – 68 HRc

(3 layer hardness)

High alloyed flux core wire for welding dissimilar steels and unknown steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 78 Kg/mm2

(1,10,000 psi)

Open arc self-shielded flux cored wire for joining and build up applications

Applications:

Typical Mechanical Properties:

Hardness: 85 – 90 HRb

Tensile Strength: 52 Kg/mm2

(73,000 psi)

Open arc self-shielded continuous wire having resistance to high impact and compression

Applications:

Typical Mechanical Properties:

Hardness (As Deposited) : 16 – 25 HRc (3 layer)

Work Hardened : 32 – 47 HRc (3 layer)

Open arc self-shielded continuous wire with high resistance to impact and pressure

Applications:

Typical Mechanical Properties:

Hardness:

As Deposited: 85 – 95 HRb (3 layer)

Work Hardened: 25 – 32 HRb (3 layer)

Open arc self-shielded continuous wire with outstanding abrasive wear resistance at elevated temperature

Applications:

Typical Mechanical Properties:

Hardness : 58 – 65 HRc (2 layer)

Open arc self-shielded flux cored wire with good resistance to impact and compressive load upto 500 deg C

Typical Mechanical Properties:

Hardness: 52 – 58

HRc (3 layer)

Open arc self-shielded flux cored wire with superior resistance to 2-body abrasion and low-to-medium impact

Applications:

For wear preventive protection of parts in

Typical Mechanical Properties:

Hardness: 50 – 58 HRc

(3 layer )

Open arc self-shielded flux cored wire with excellent resistance to 3-body abrasion and moderate-to-heavy impact

Applications:

For wear protective coatings of

Typical Mechanical Properties:

Hardness: 45 – 55 HRc (2 layer)

Open arc self-shielded flux cored wire for joining, fillet welding and build-up applications

Applications:

Typical Mechanical Properties:

Hardness: 20 – 32 HRc

Tensile Strength: 58 Kg/mm2 (82,000 psi)

Download

FCAW Wire for Drop Forging Tools & Dies

Applications:

Typical Mechanical Properties:

Hardness: 40 – 46 HRc (as welded)

38 – 45 HRc (after tempering at 550-600 °C for 1hr per inch job thickness)

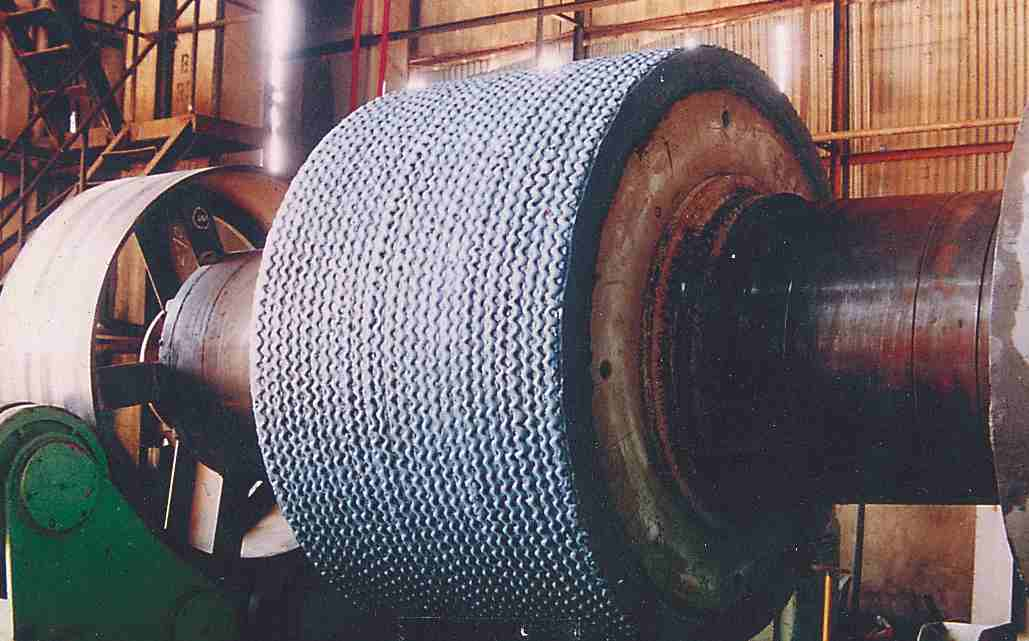

Open arc self-shield continuous wire for build-up of table and roller liners

Applications:

Hardness: 56 – 62 HRc

Download