EWAC is the pioneer in manufacturing wear plates in India since 1994. Our company contributed significantly to the life enhancement of components for customers across all gamut of Industries.

EWAC continuously improves the quality of the wear plates and increases the varieties to suit the varied needs of the Industrial applications to fight against extreme working conditions. We also develop custom-made wear plates for specific application demands of customers.

EWAC constantly strives to introduce the state-of-the-art technology in the Indian Industry Wear Plate Segment, thereby introducing many first of its kind products in partnership with world-class manufacturers. The product range is as follows-

With the help of our R&D facility, which is the only welding consumables manufacturing facility approved by DSIR (Department of Scientific & Industrial Research – A Govt. of India), we can develop and design wear parts for any critical applications.

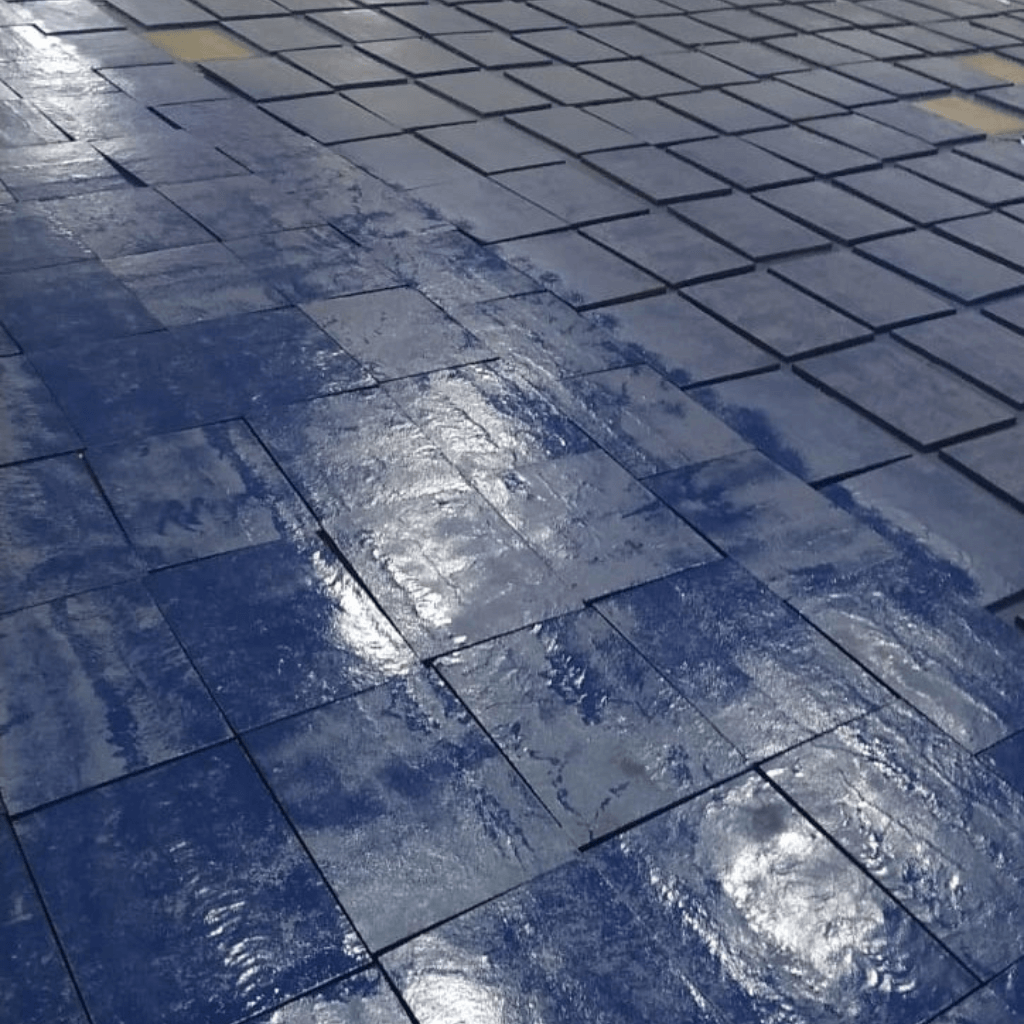

SSWP is a heat treated Smooth Surface Wear late for high abrasion and impact resistance applications in Cement, Steel, Mining & Construction Industries. This is easily formable, weldable. It through hardness provides longer service life in application.

SSWP 400 is a heat-treated smooth surface wear plate for high abrasion resistance applications in mining, steel, cement and construction industries. Can be easily welded, cut and formed for accurate fabrication. Through- hardness of the plate provides longer service life.

Applications:

SSWP 400 is suited for applications involving high impact and moderate abrasion. Applications include Chute Liners, Truck Beds, Dipper Liners, Shovels, Bucket Liners, Scrapers, Screens, Crusher Parts, Conveyors, Hoppers, Chute liners, Bin and hopper liners, Construction and mining bucket liners, Mold board liners, Scrapper liners.

Hardness: 400 BHN

Download

SSWP 500 is a heat-treated smooth surface wear plate for high abrasion resistance applications in mining, steel, cement and construction industries. Can be easily welded, cut and formed for accurate fabrication. Through- hardness of the plate provides longer service life.

Applications:

SSWP 500 is suited for applications involving high impact and moderate abrasion. Applications include Chute Liners, Truck Beds, Dipper Liners, Shovels, Bucket Liners, Scrapers, Screens, Crusher Parts, Conveyors, Hoppers, Chute liners, Bin and hopper liners, Construction and mining bucket liners, Mold board liners, Scrapper liners.

Hardness: 500 BHN

DownloadYour Reliable Workhorse For Combating Erosion, Abrasion, Impact and Hang-ups.

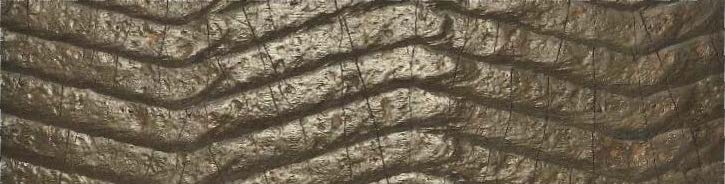

EWAC TUNGPLATE S6 is a WC cladded Wear Plate specially designed for severe abrasive wear resistant conditions even at elevated temperatures. Ultra-hard WC particles (Angular / Spherical / Macrocrystalline) are uniformly distributed in tough nickel alloy matrix without stress-relieving cracks on the cladded surface.

Typical Applications:

Applications involving sliding, grooving, rolling impact wear.

Wear properties up to 600 °C combined with good corrosion resistance.

Hardness : 60 – 65 HRc

Download

EWAC resistant HardGlide Cast-O-fuse is the overlay world’s plate. most The presence revolutionary of wear extra high density and ultra-abrasion resisting alloy with blend hardness provides high resistance to Abrasion, Erosion and Impact.

Hardness: 56 – 62 HRc

Download

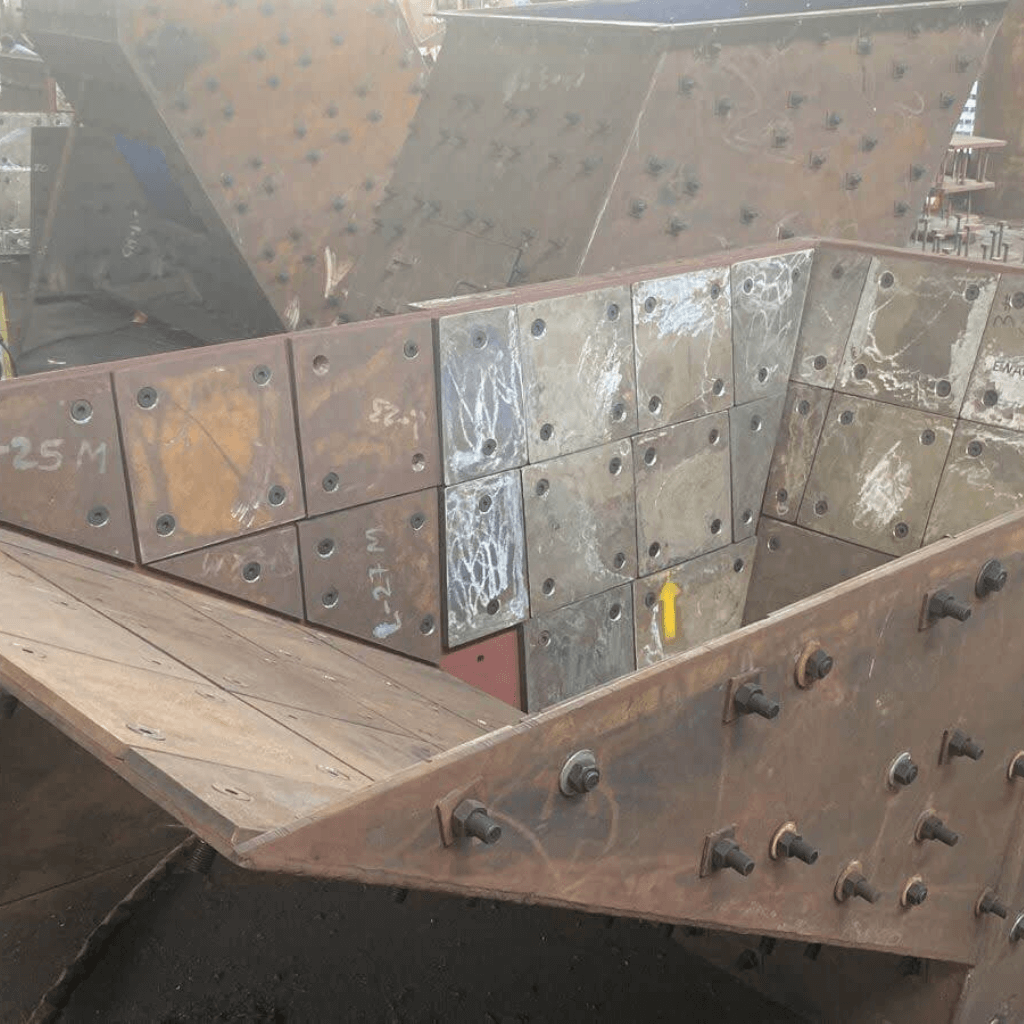

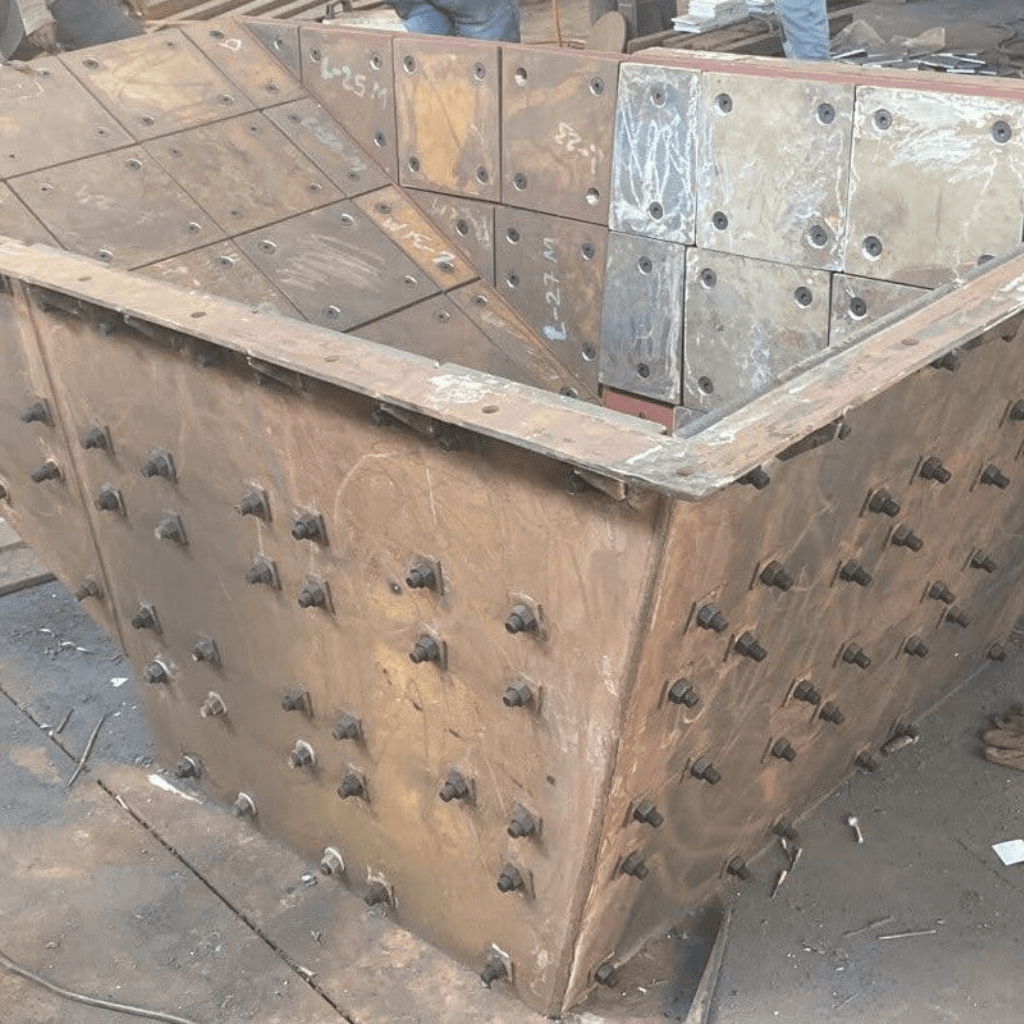

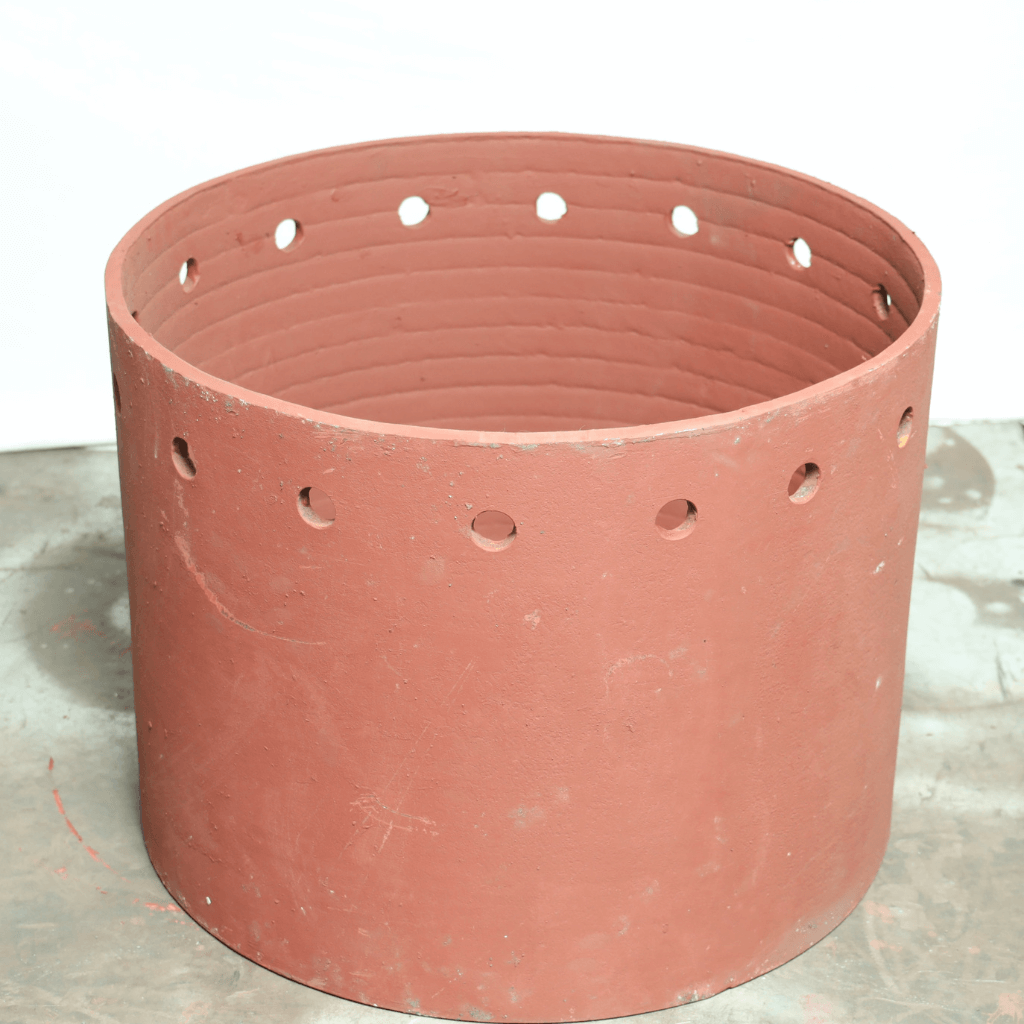

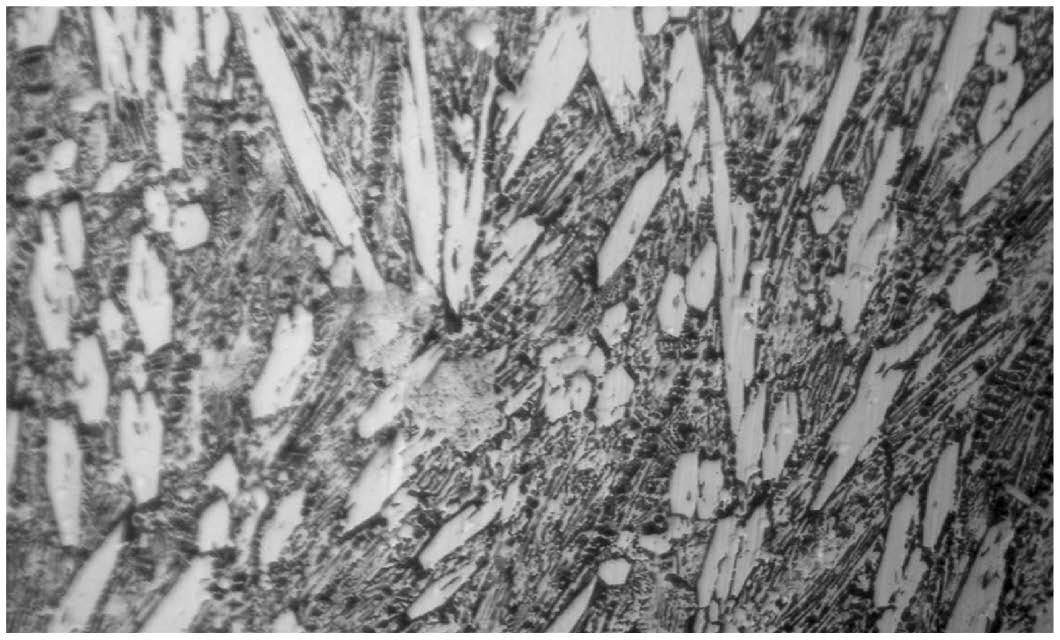

EWAC Bimetallic wear plate is a combination of high chromium-high carbon alloy casting metallurgically bonded to a mild steel base plate. The wear surface is smooth and flat. Resistance to severe abrasion and high impact service conditions.

Typical Applications:

Chutes, hoppers, bins, liners, impact walls, rock boxes etc.

Hardness : 63 – 66 HRc

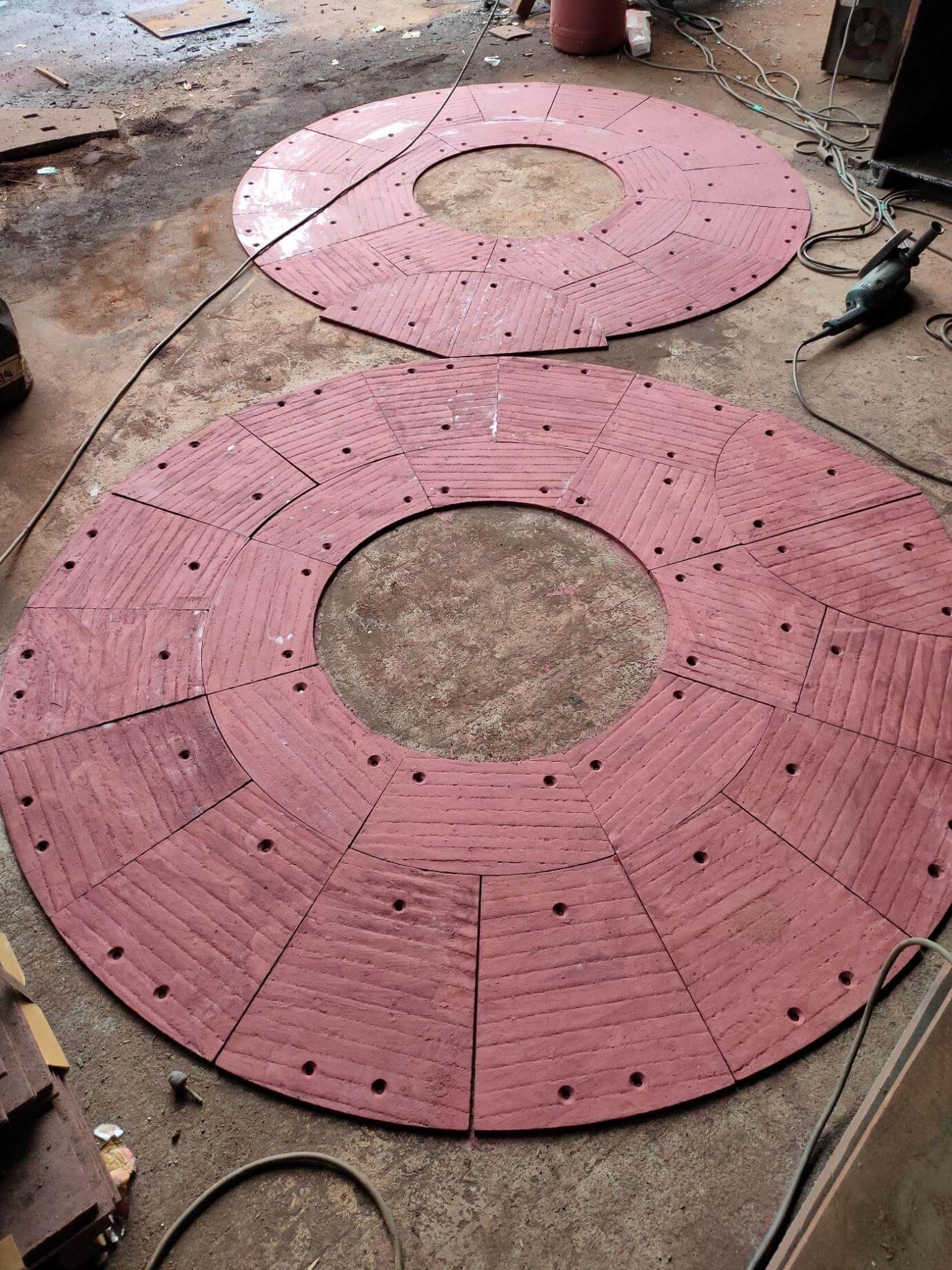

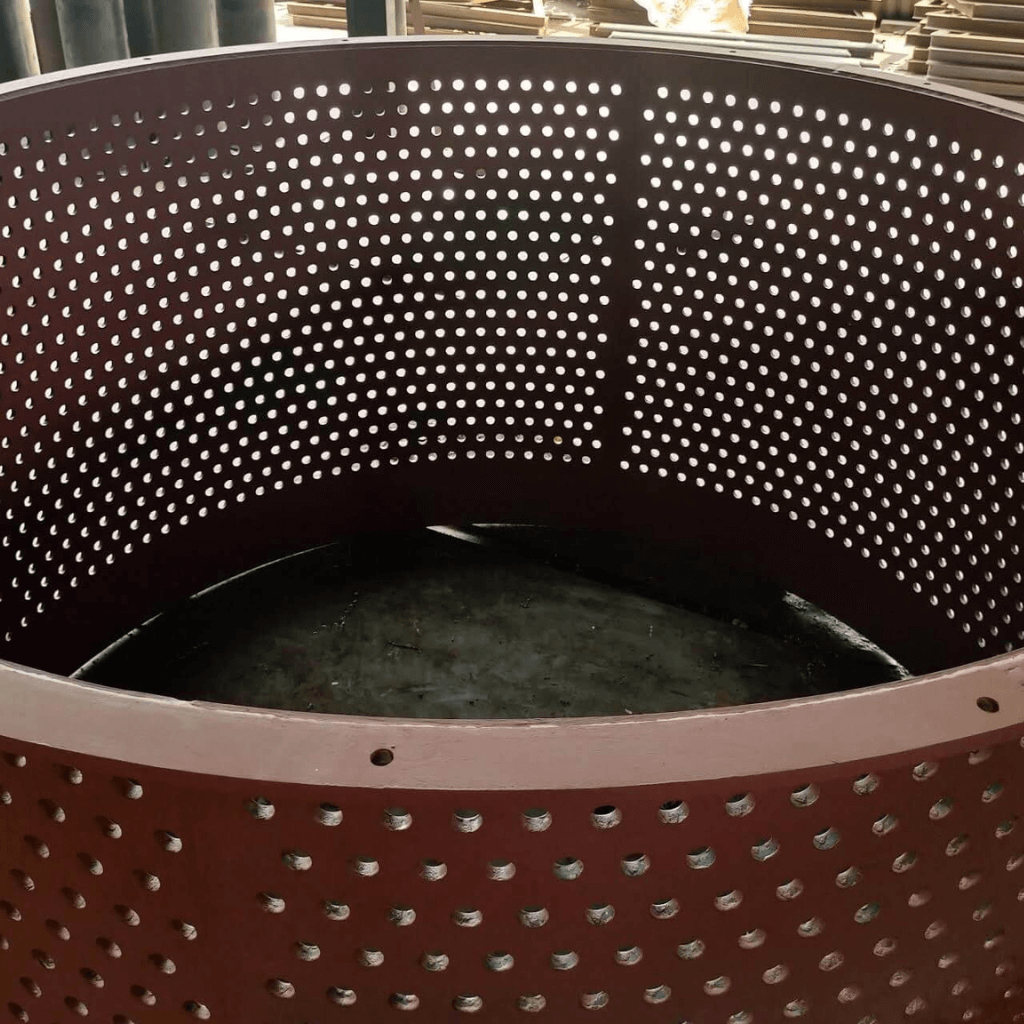

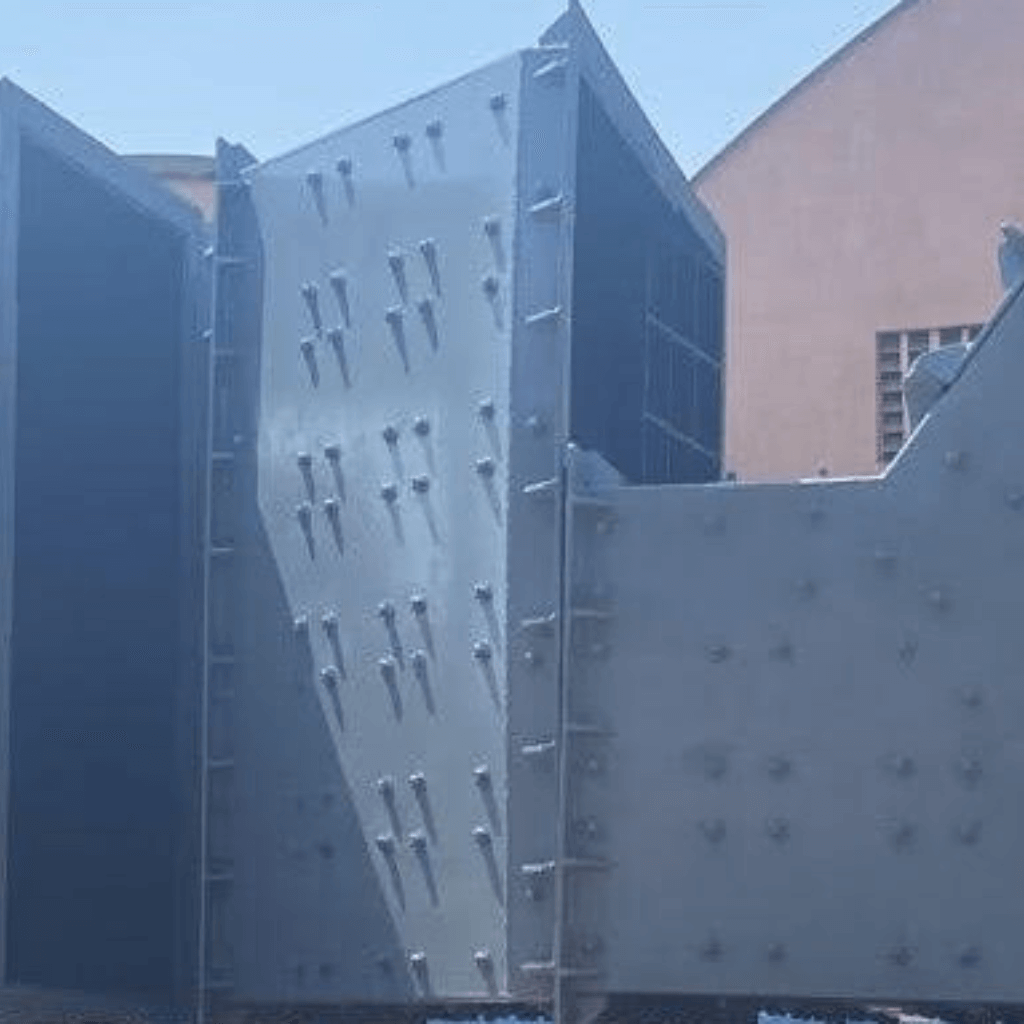

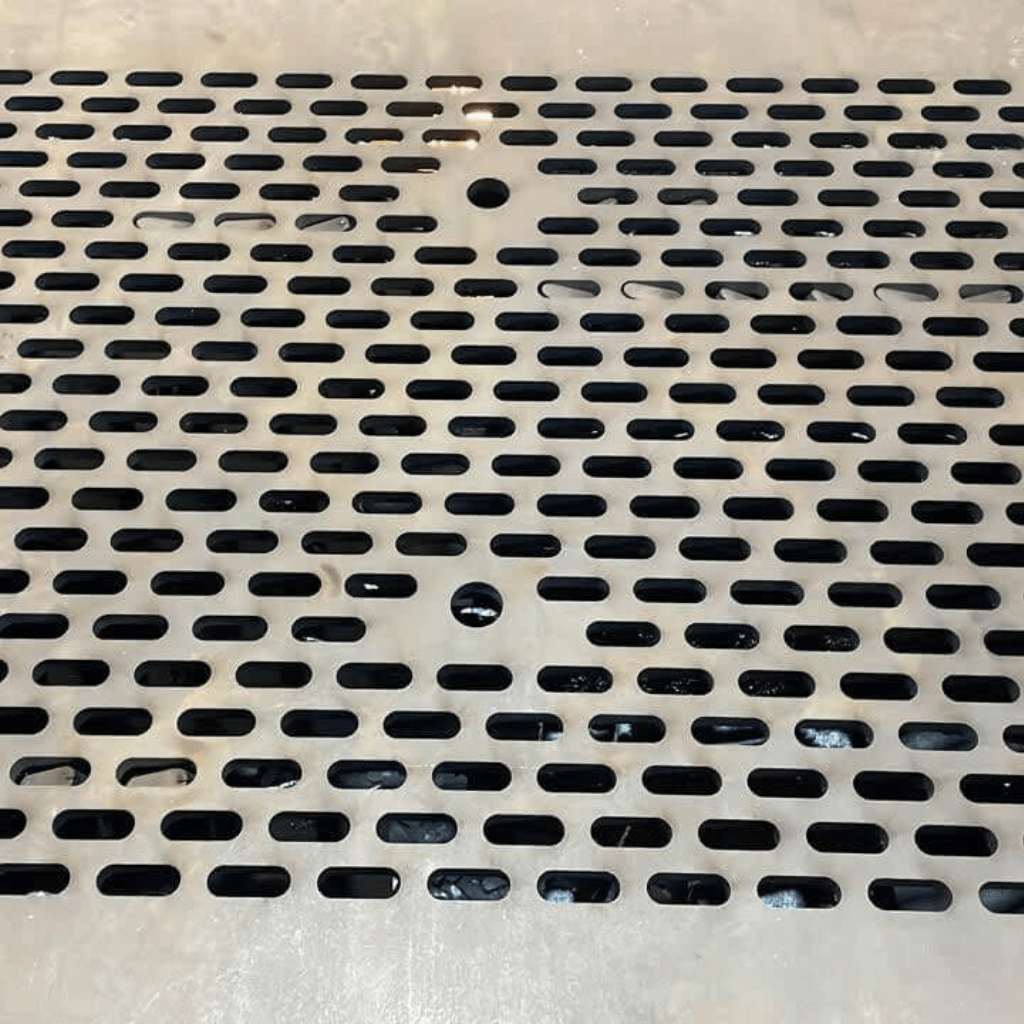

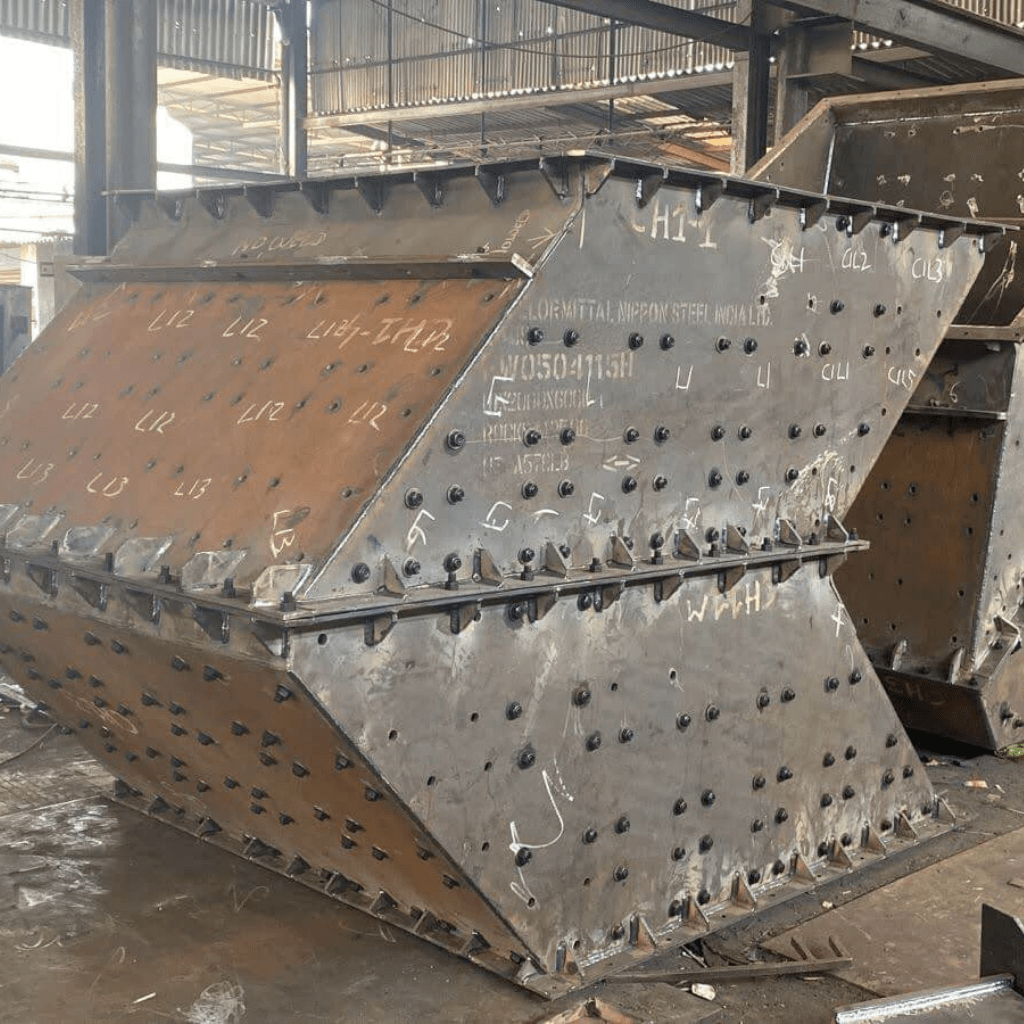

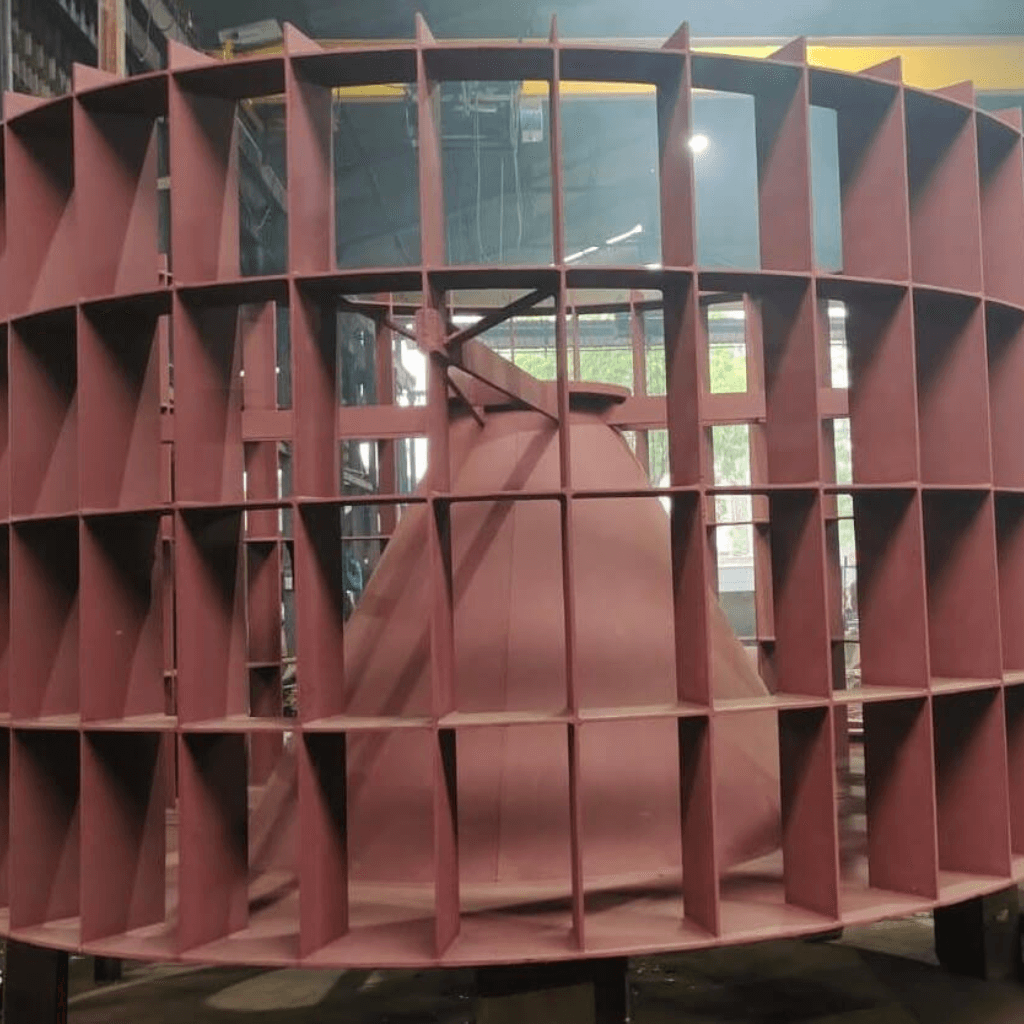

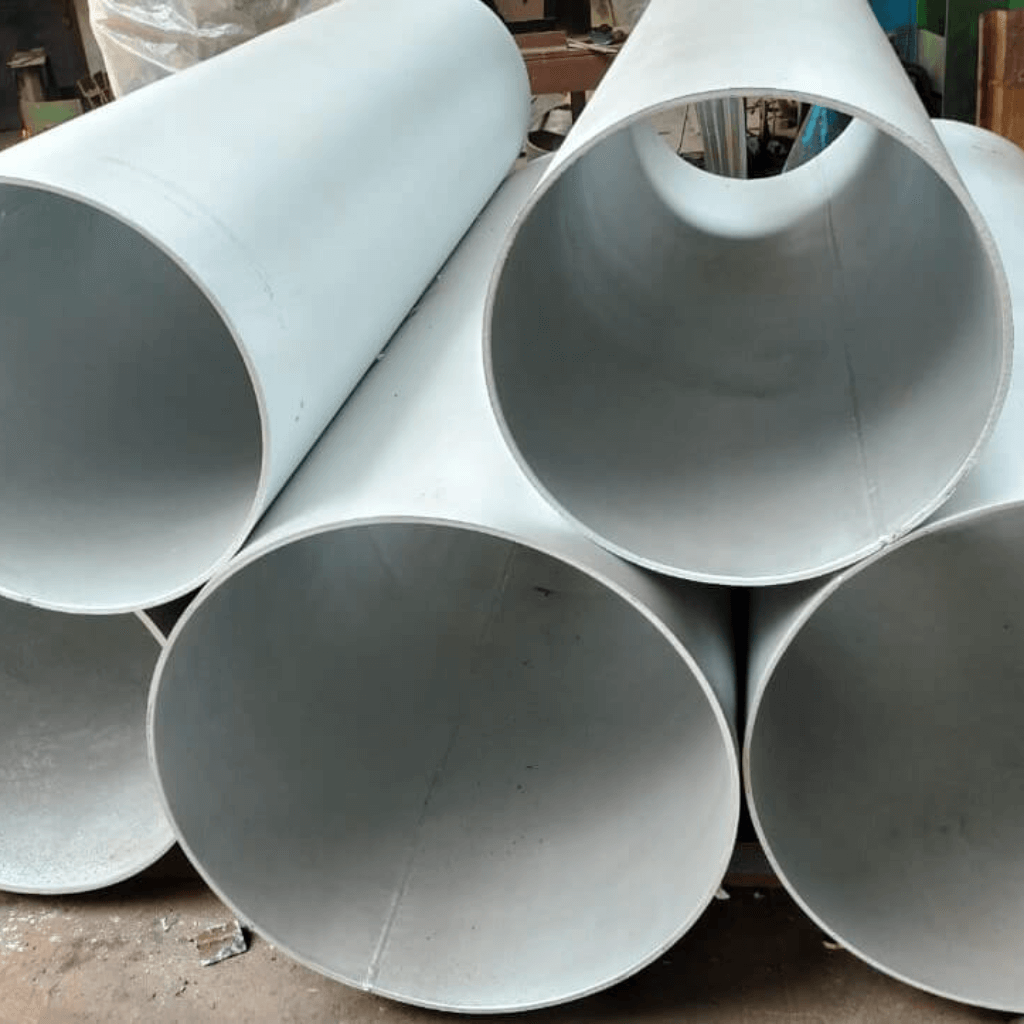

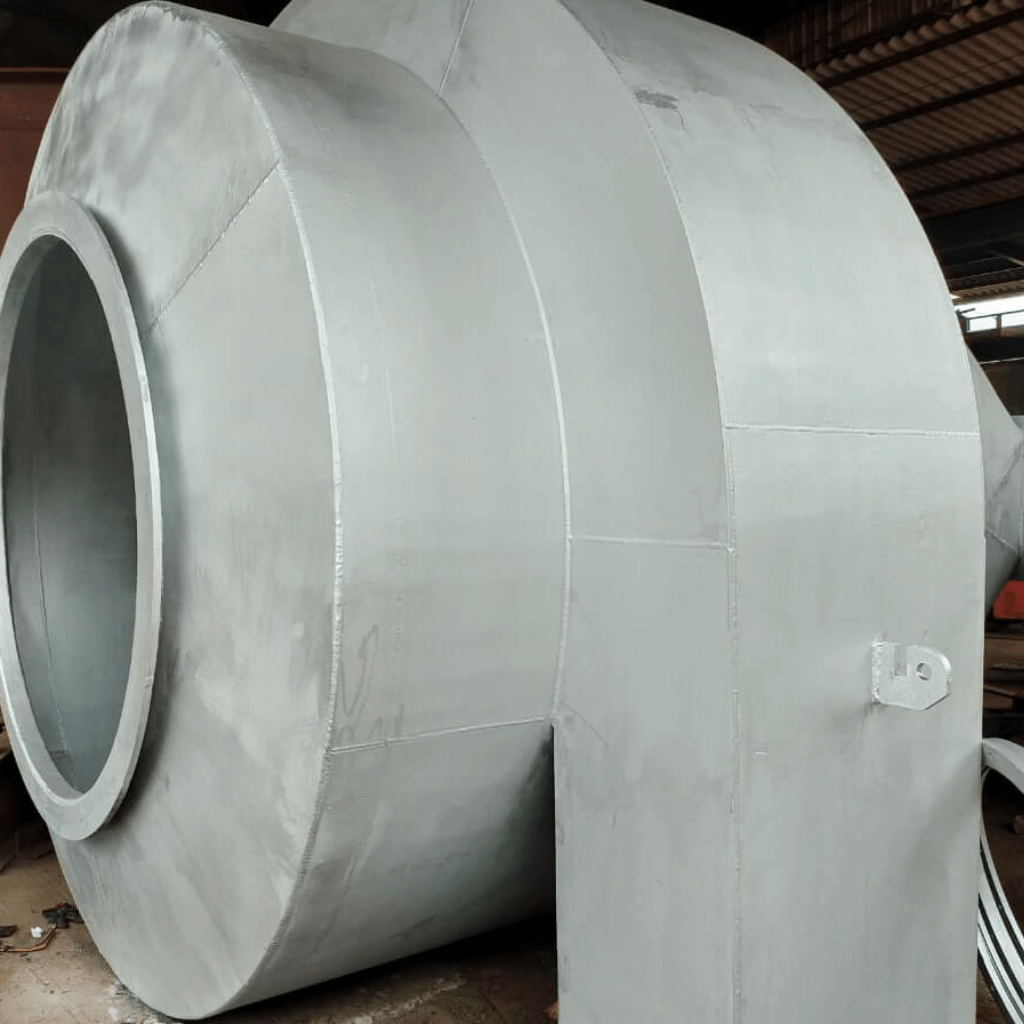

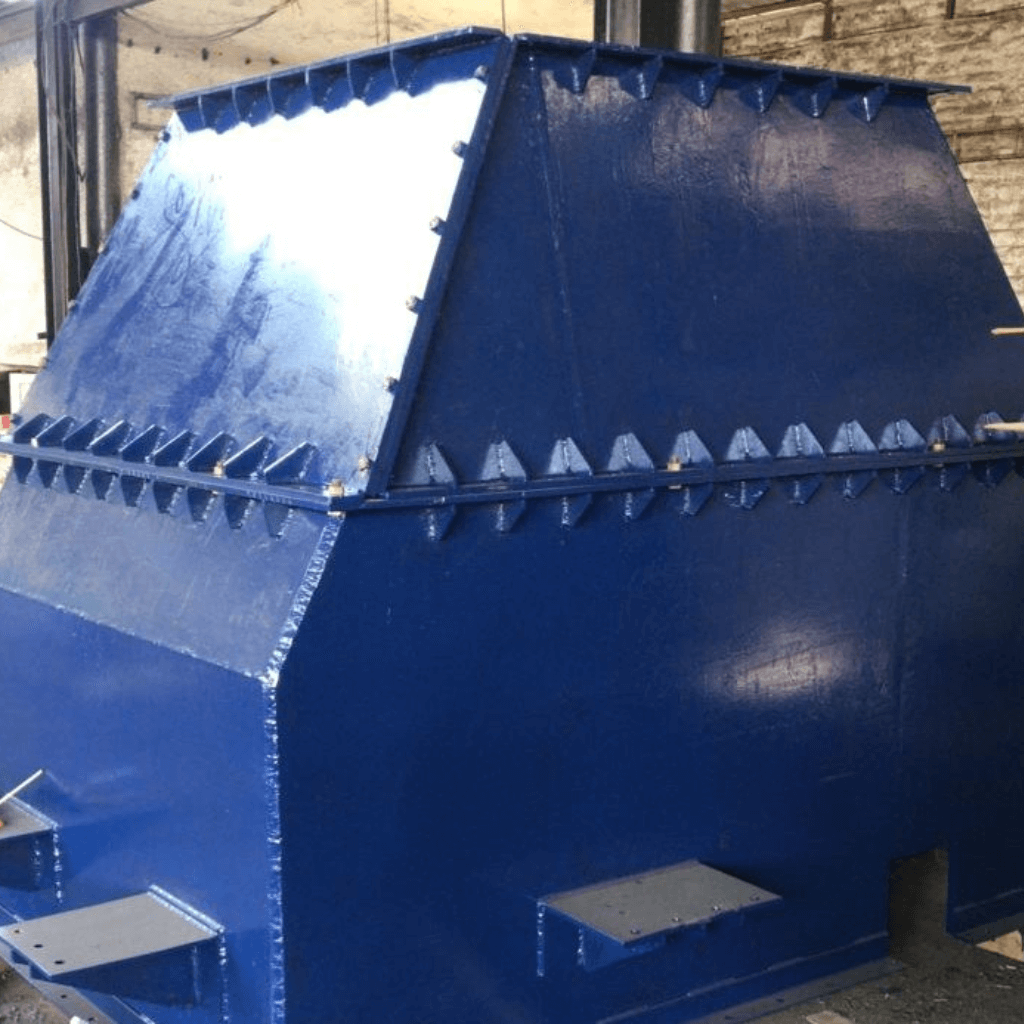

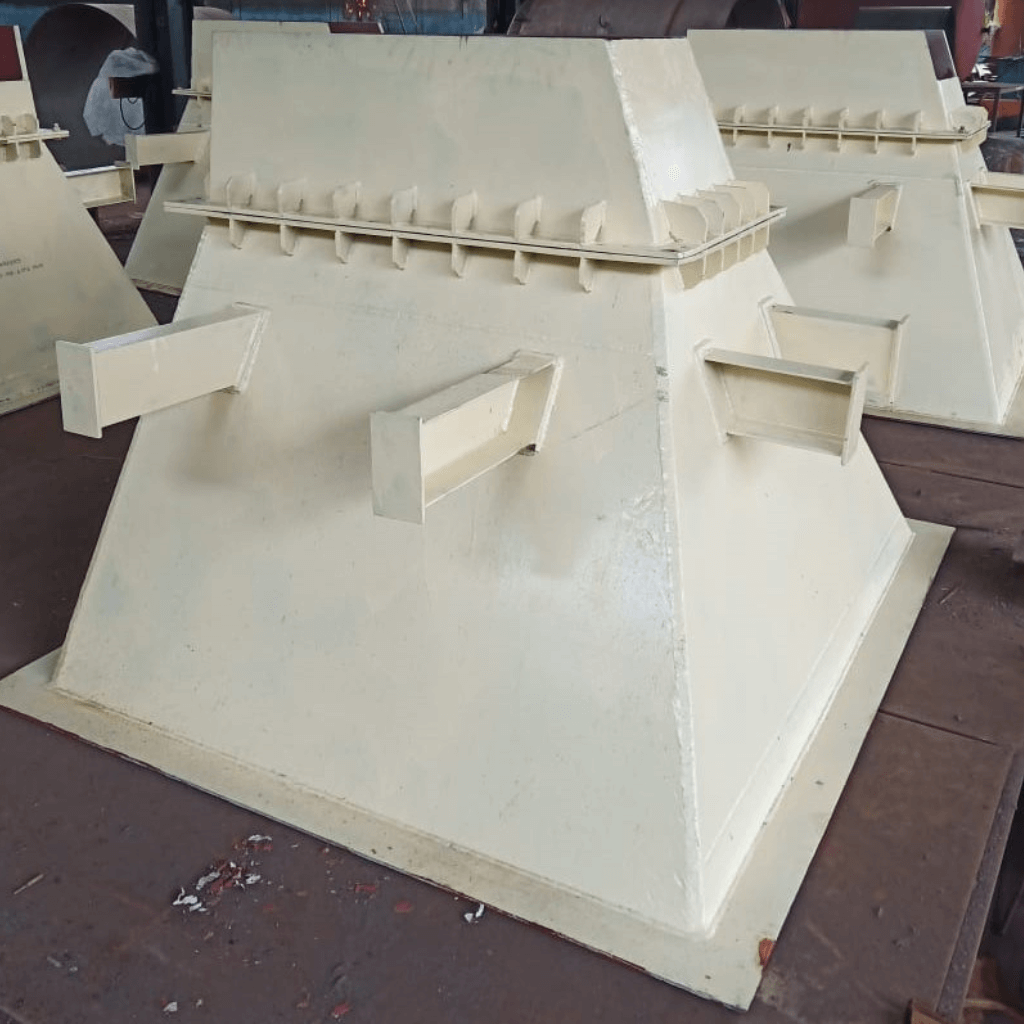

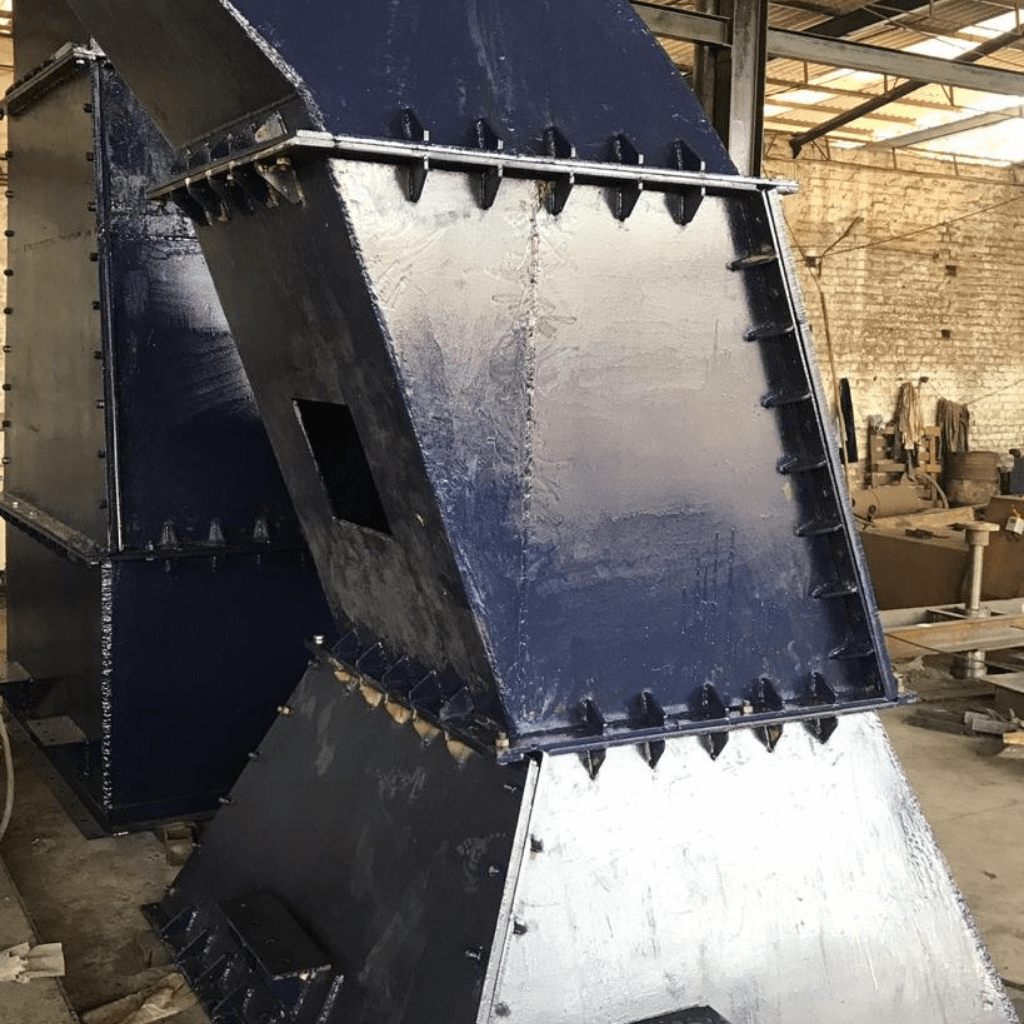

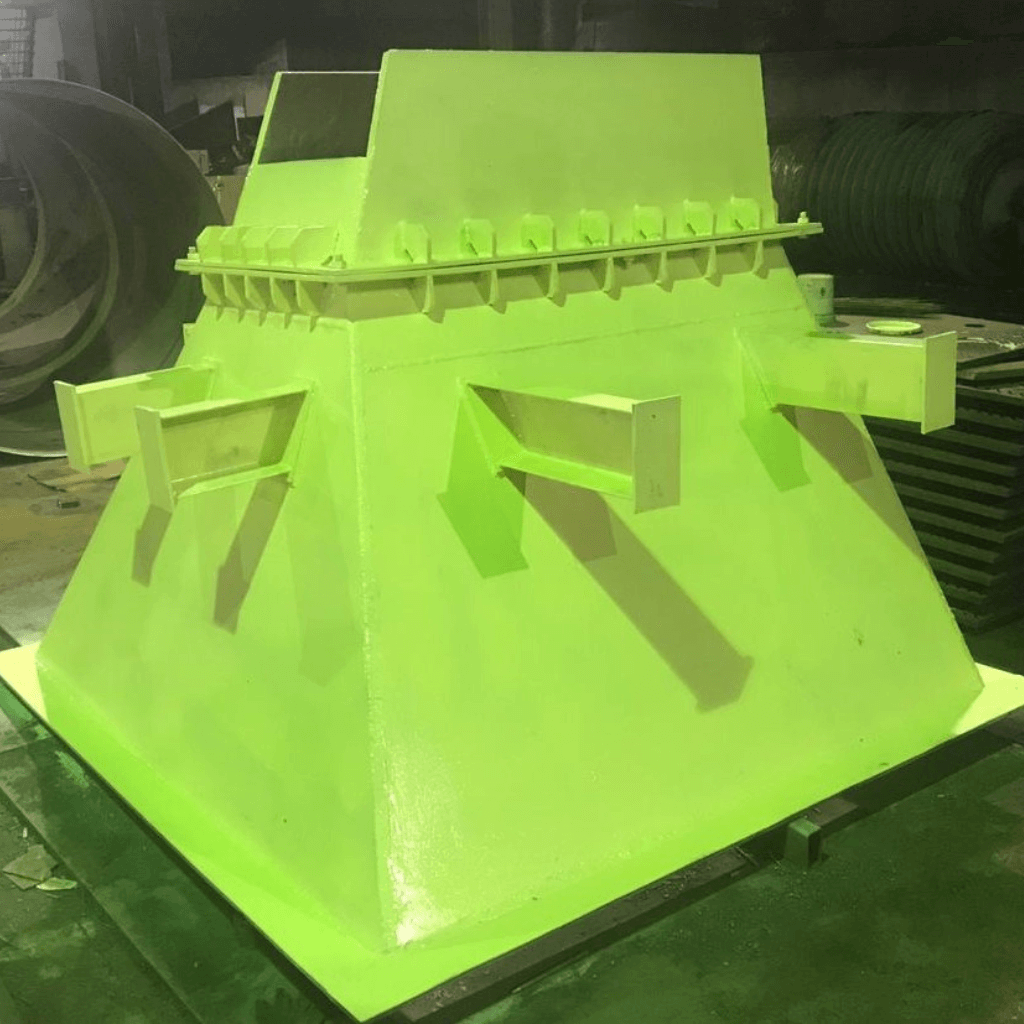

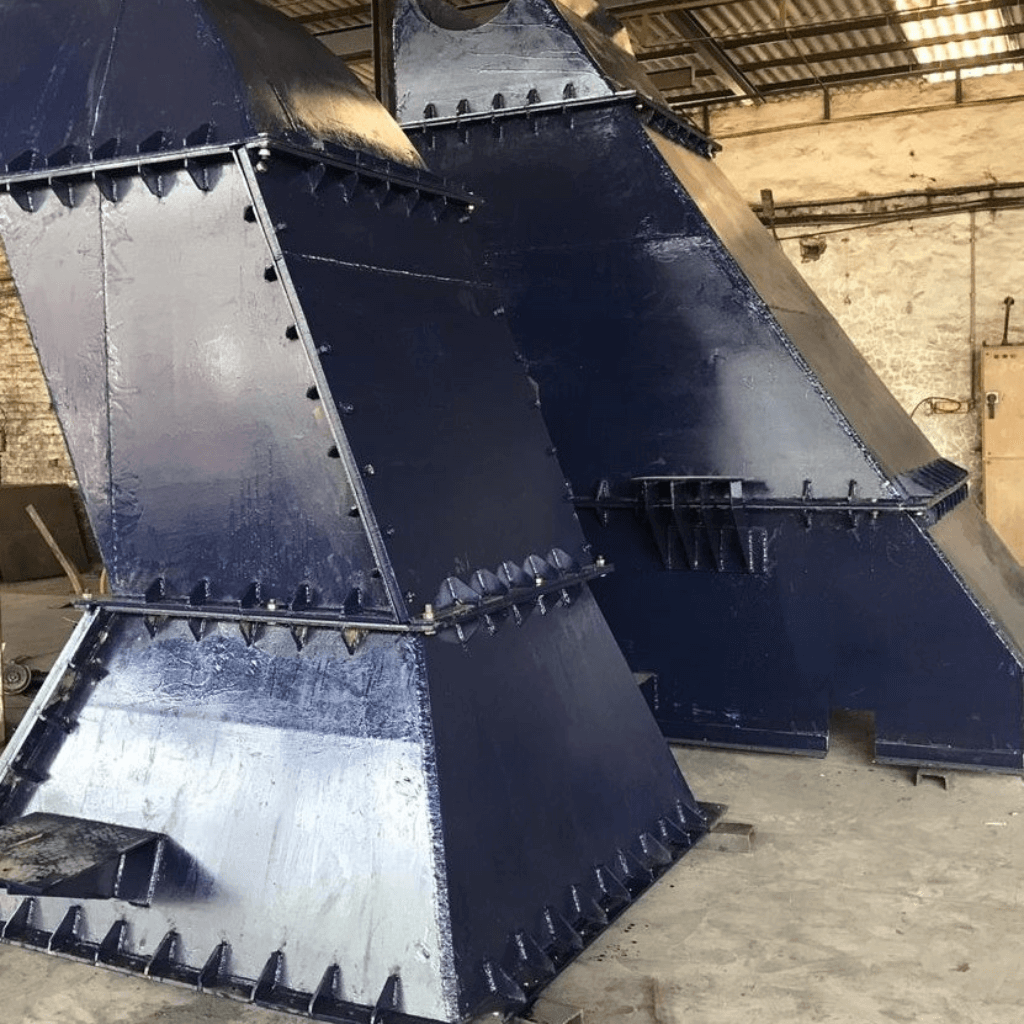

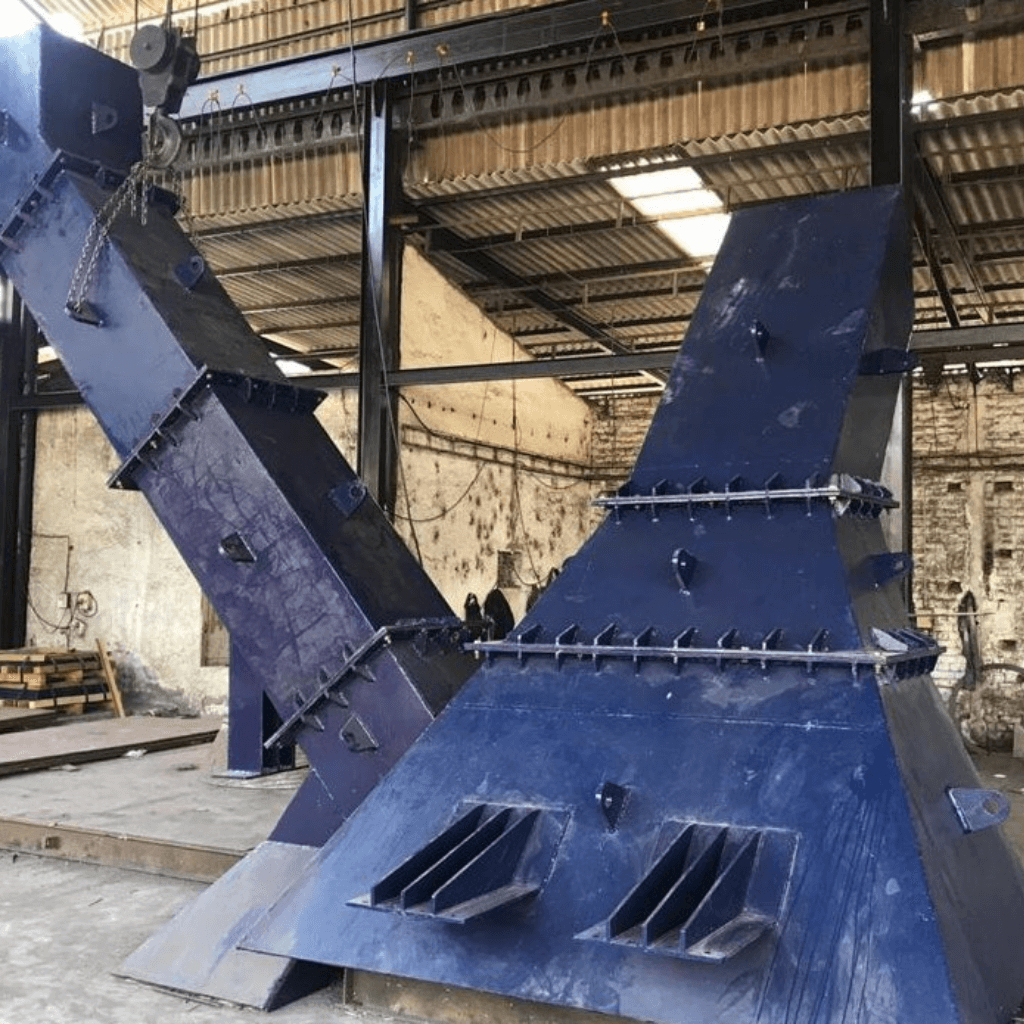

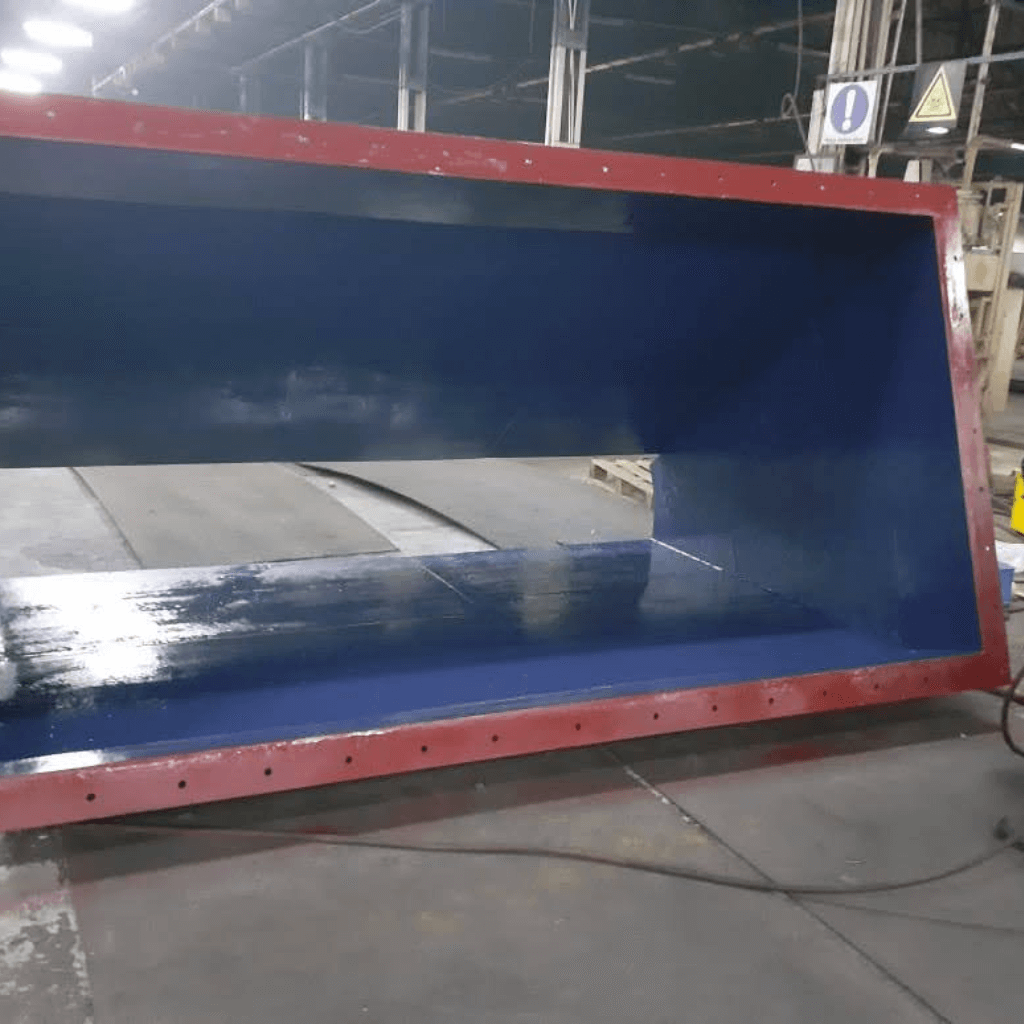

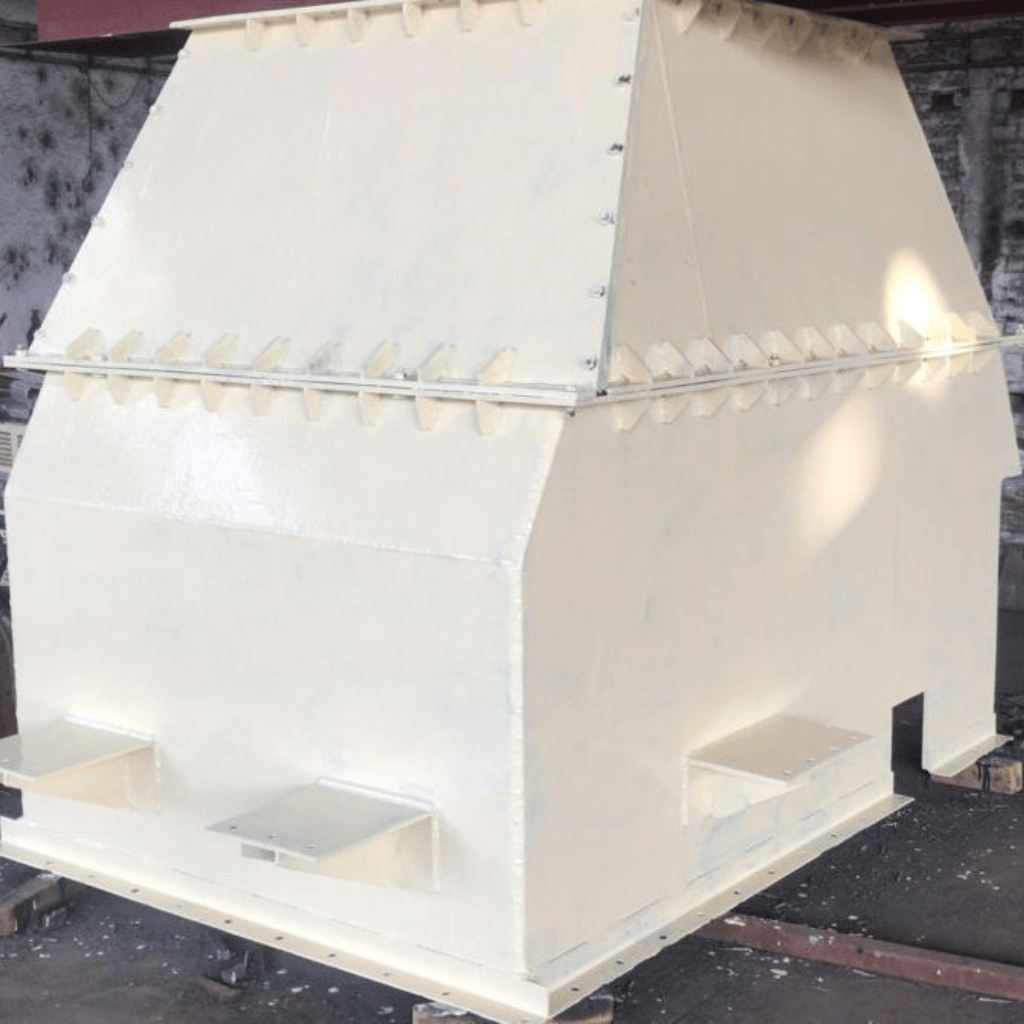

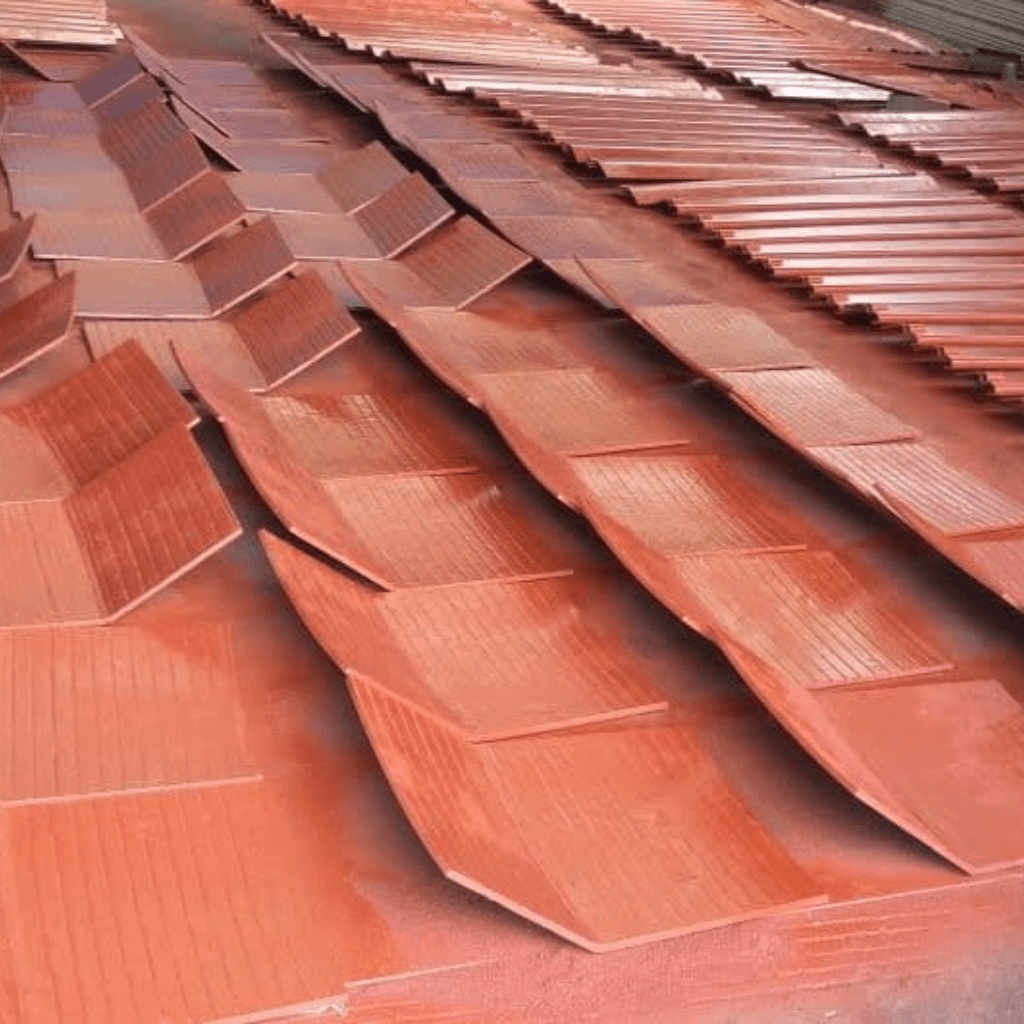

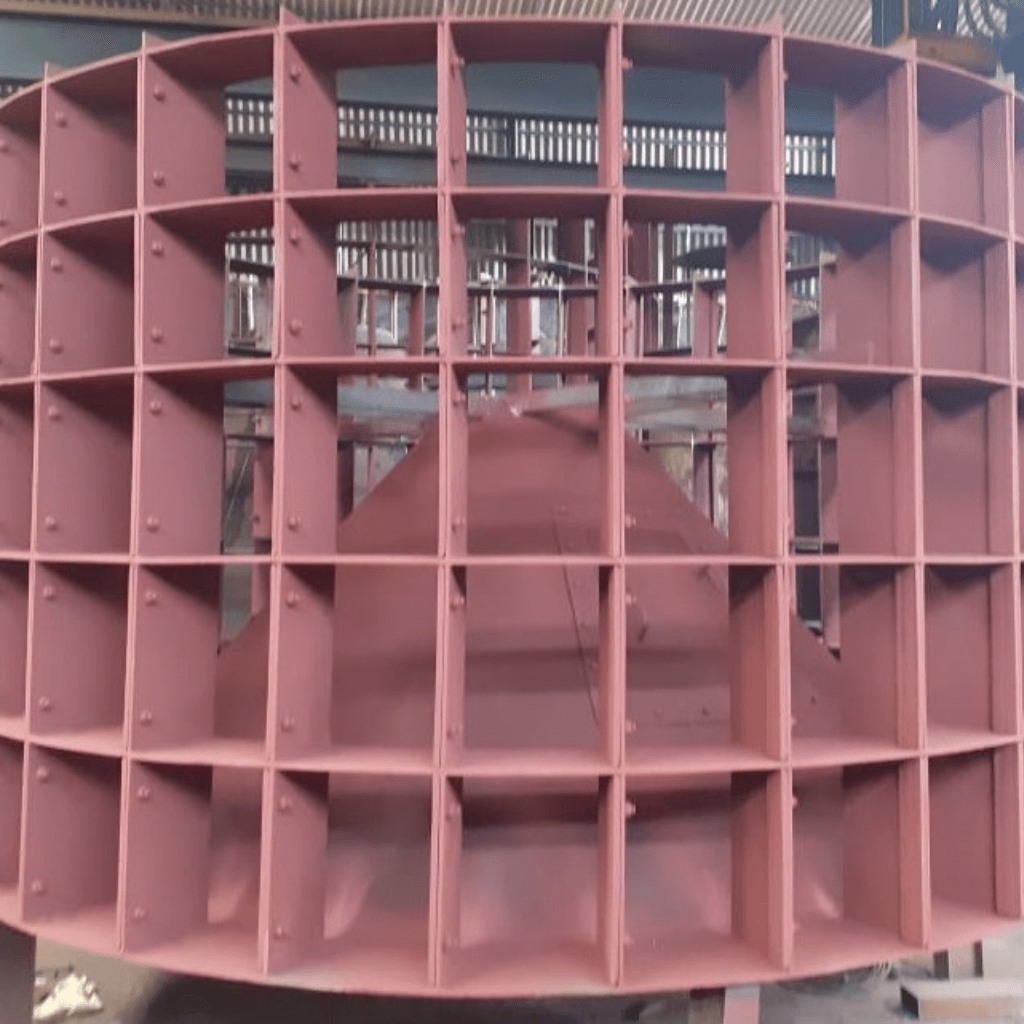

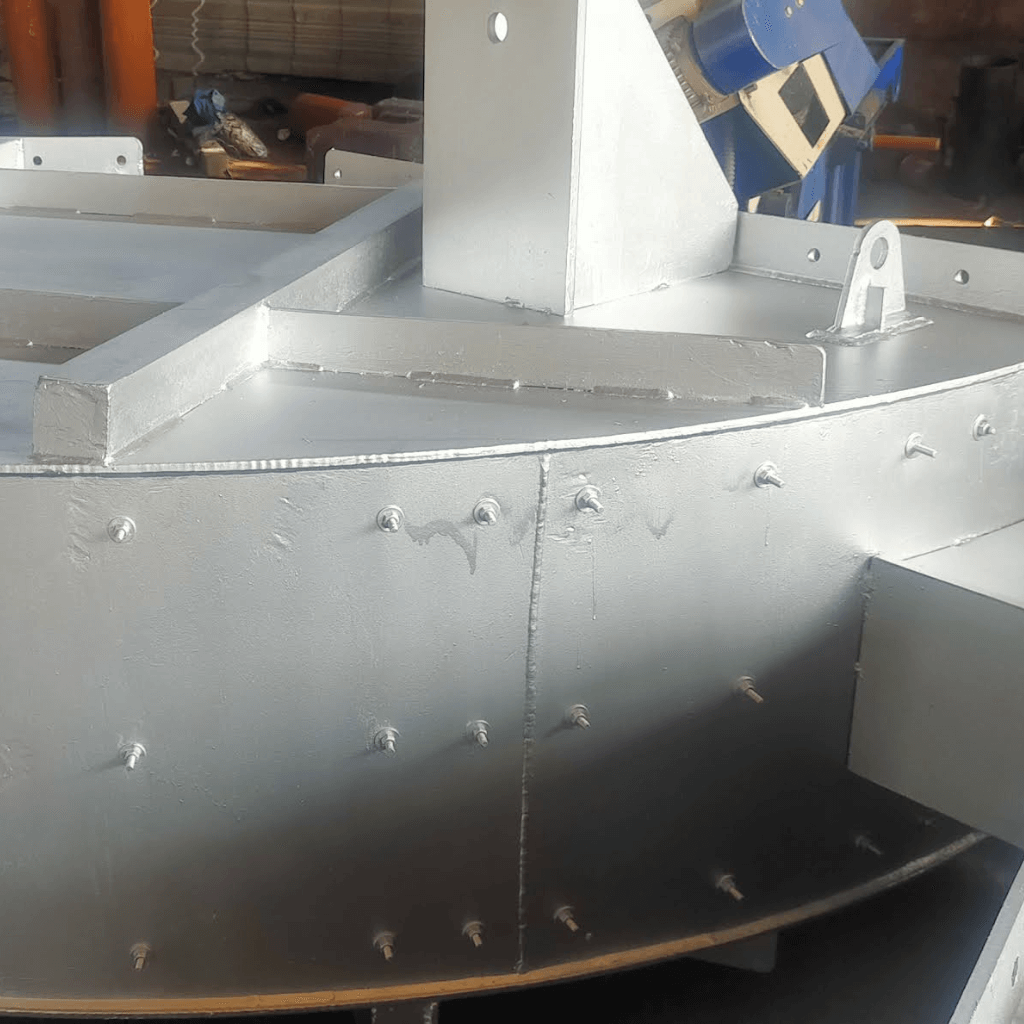

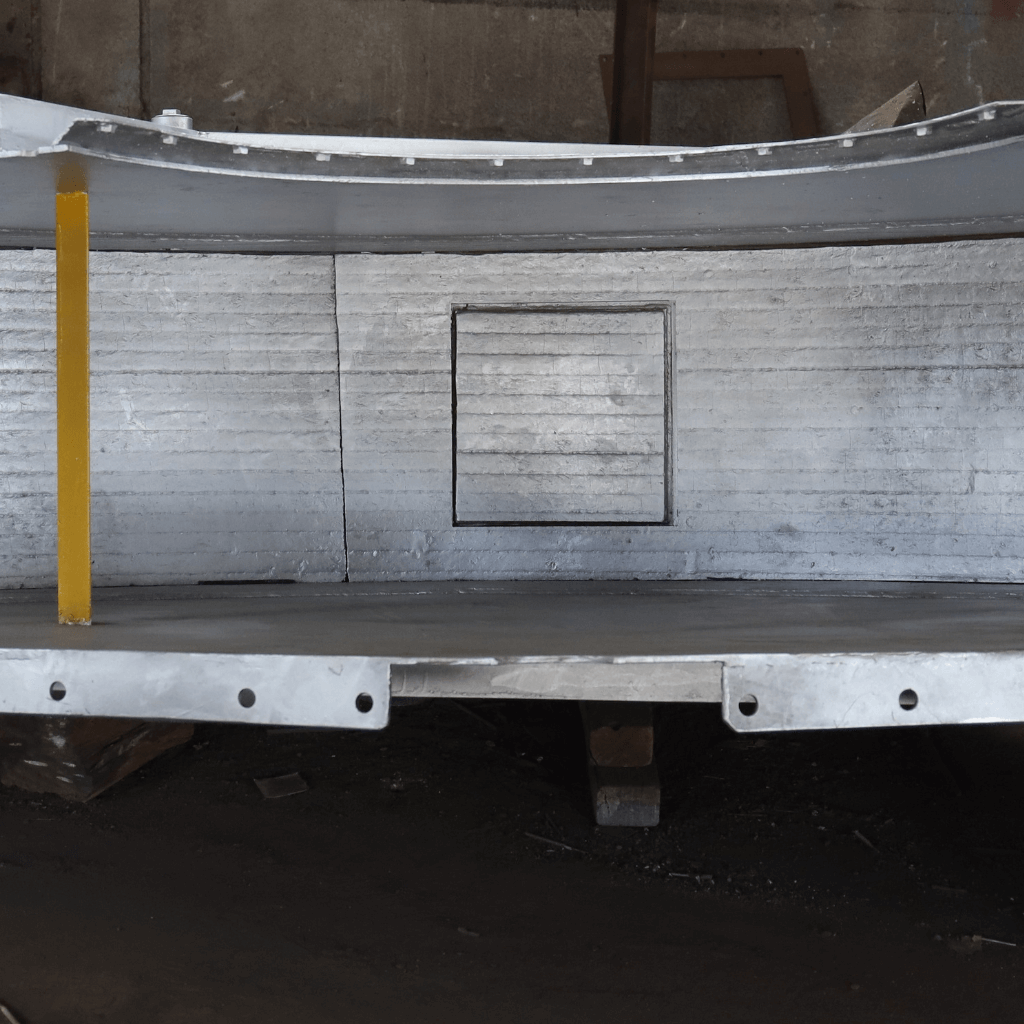

DownloadEWAC undertakes the fabrication of problematic material handling bins, hoppers, chutes etc., by studying the material handled and its wear factors. Our 60 years of leadership in M&R applications, time tested skill and expertise are used to design the components for guaranteed high performance and longer life.

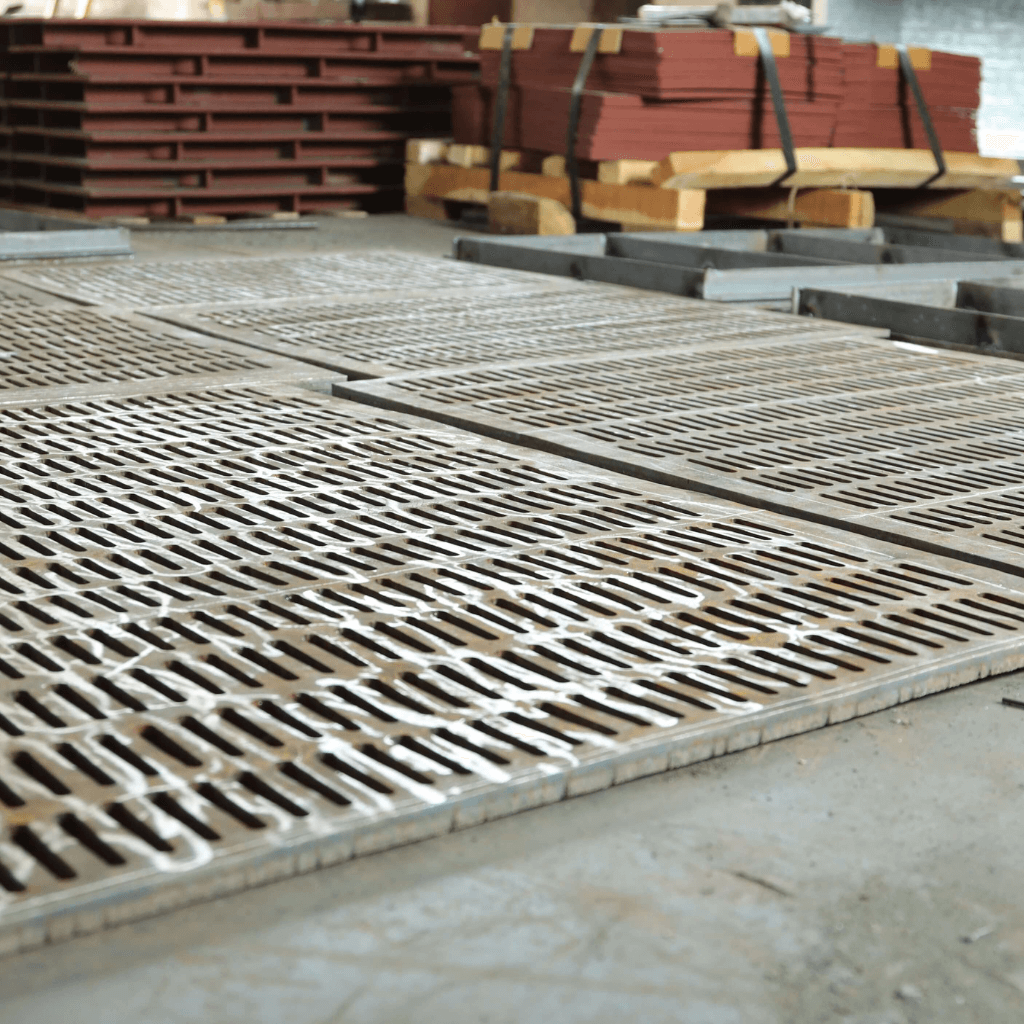

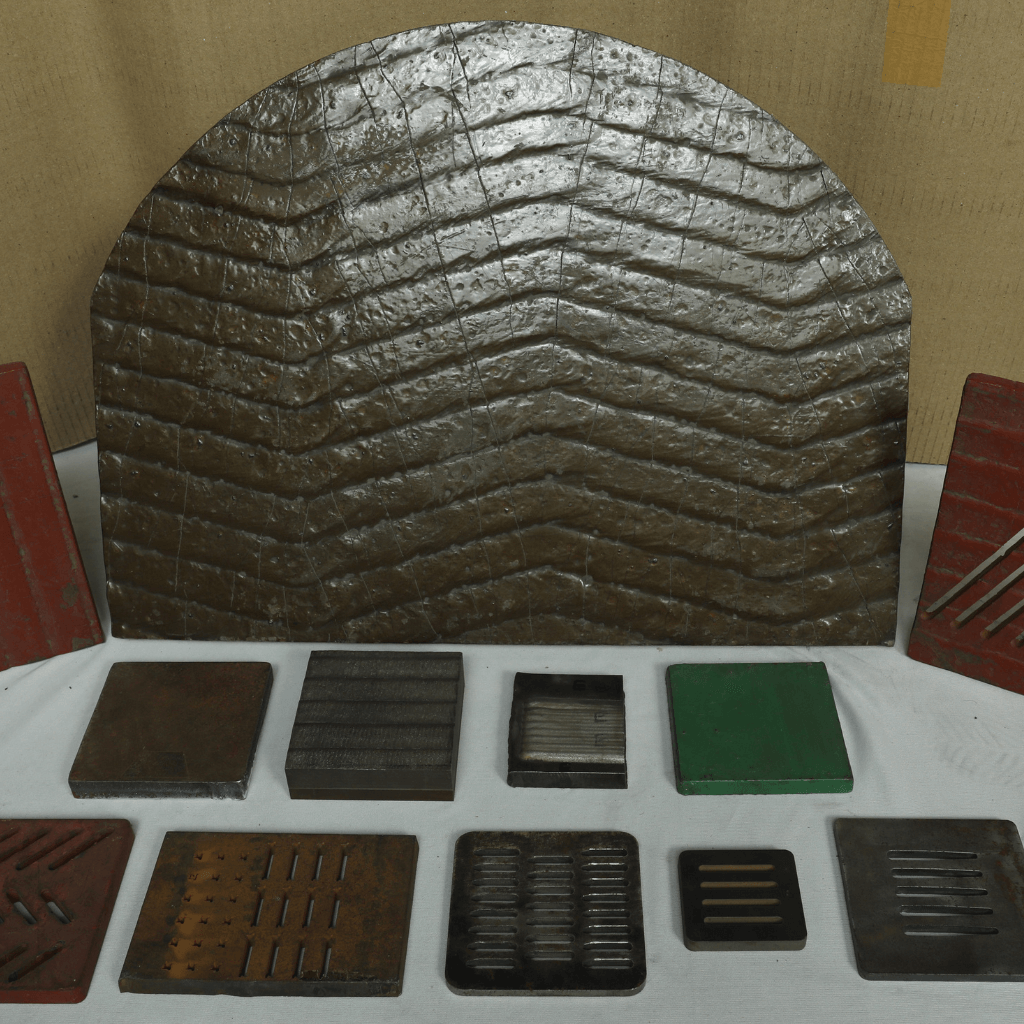

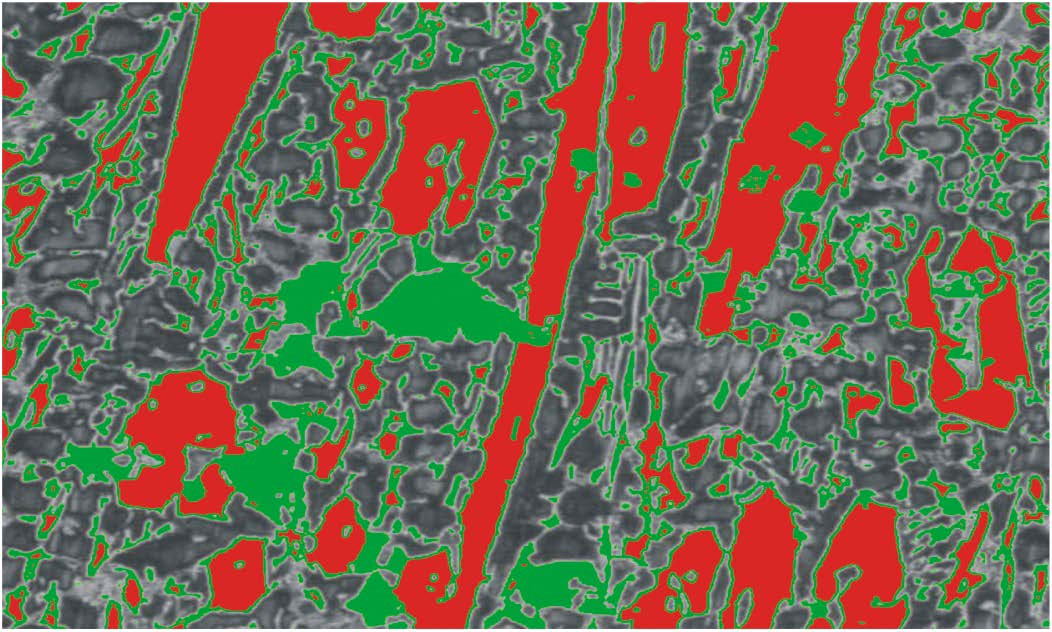

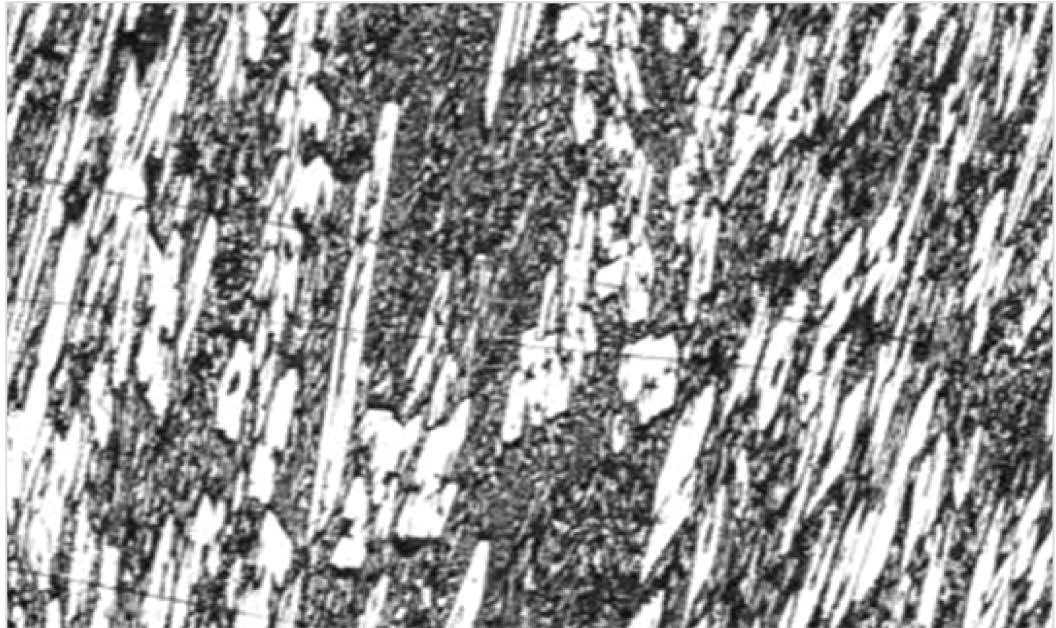

We manufacture a wide range of wear plates, in terms of sizes, thicknesses, base materials, coating alloys and welding processes.

Our alloy chemistry starts from simple chromium carbide rich overlays to sophisticated refractory complex carbides, to meet diverse application needs.

Weld bead patterns like Straight beads, Bavarian beads, E-wave beads, S-Wave beads etc. are available.

Wear Plate with Outstanding Abrasion Resistance at Elevated Temperatures upto 750 °C

Typical Applications:

BLT distribution chutes, Moveable throat armour (MTA) plates, Hot gas ventilators, Feeder spout, Hot gas ducts/pipes upto 750 °C.

Hardness: 59-64 HRc

Download

Wear Plate for Applications involving Severe Abrasion and Erosion at Elevated Temperatures upto 450 °C

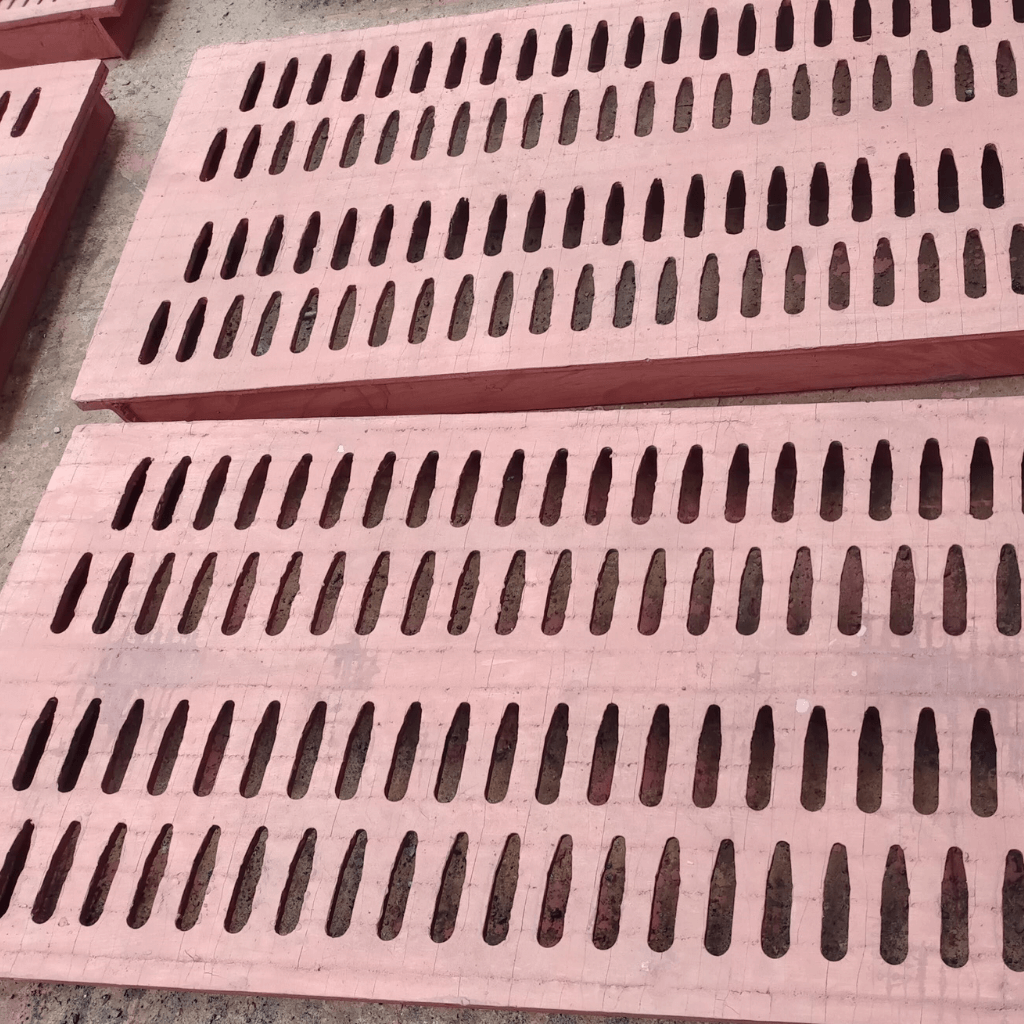

Typical Applications:

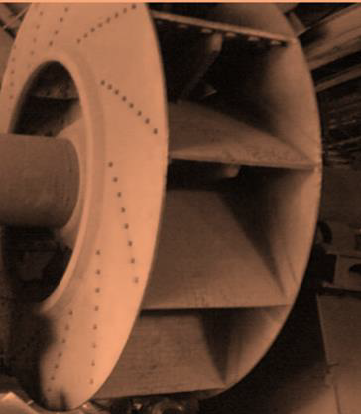

Components subjected to high abrasion and erosion and moderate impact up to 450°C. Impeller blades, Casings, Sinter screen, Sinter ducts, Wear protection covers, Liners, Fan blades, Louvers, etc.

Hardness: 58-64 HRc

Download

Wear Plate with Superior Abrasive Wear Resistance

Typical Applications:

Transfer chutes, Hoppers, Bins, Pipe chutes, Housings, Casings, Louvers, Cyclones, Micro-feeders etc.

Hardness: 58 – 62 HRc

Download

EDP 600 is an iron-chromium-carbon alloy system containing micro-alloying Elements. Designed especially for wear resistance applications upto 350 Deg C.

Typical Applications:

Guide vanes, Fan blades, Louver plates, Nozzle ring segments, Wear

cover, Mill body liners, Coal mil louvers, Mixer blades, Conveyor chutes etc.

Hardness: 60 – 63 HRc

Download

EDP 560 is an iron-chromium-carbon alloy system containing micro-alloying Elements. Designed especially for wear resistance applications upto 350 Deg C.

Typical Applications:

Guide vanes, Fan blades, Louver plates, Nozzle ring segments, Wear cover, Mill body liners, Coal mil louvers, Mixer blades, Conveyor chutes etc.

Hardness: 58 – 64 HRc (depending on thickness)

Download

Wear Plate for Applications involving Severe Abrasion and Moderate Impact

Typical Application

Hardness : 54-58 HRc

Download

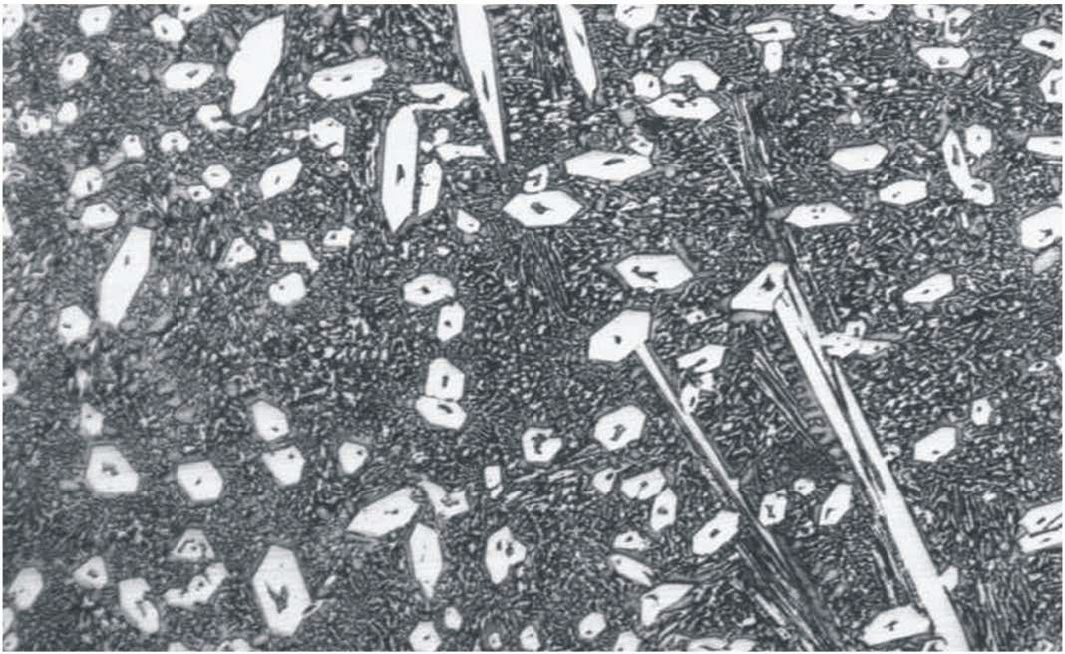

Unique composite wear plate for heavy impact combined with pressure and abrasion

Typical Applications:

Secondary crusher discharge chutes, Crusher bodyliners, Material handling impact zone liners, Flapper gates, Impactor liners, Deflector plates, etc.

Hardness: 50 – 60 HRc (First layer)

45 – 55 HRc (Second layer)

Wear plate with improved cutting resistance – both by abrasive wheel and flame which delays cutting time to combat burglar

Typical Application:

Strong rooms, vault doors, safes, safe deposit lockers, security doors etc

Hardness: 54 – 58 HR

Download

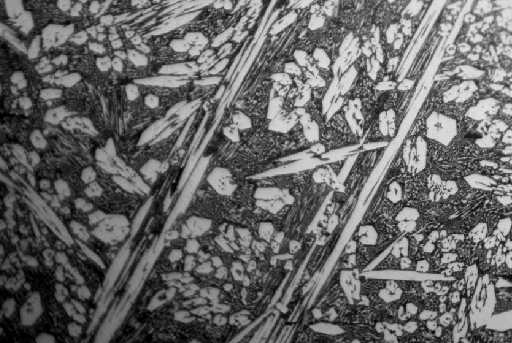

EDP 700 is an iron-based surfacing alloy system containing ultrahard constituents to withstand severe erosive wear. Service temperature of this alloy is restricted to 300 °C.

Typical Applications:

Exhauster fan blades, Guide vanes, Louver plates, ID fans, Classifiers, Separators, etc.

Hardness : 65 – 68 HRc

Download