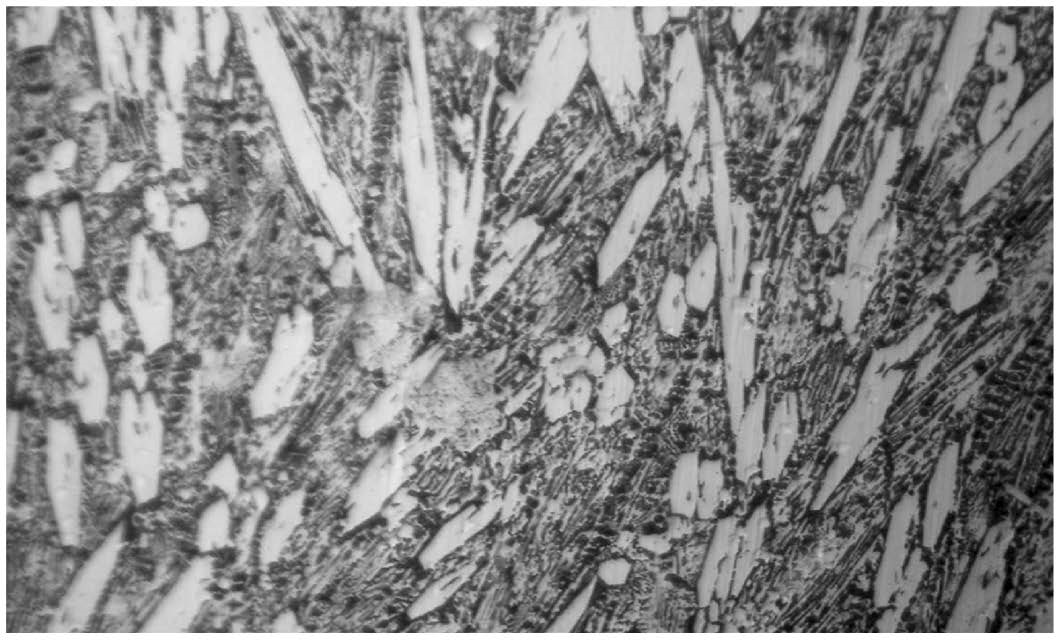

Wear Plate for Applications involving Severe Abrasion and Erosion at Elevated Temperatures upto 450 °C

Typical Applications:

Components subjected to high abrasion and erosion and moderate impact up to 450°C. Impeller blades, Casings, Sinter screen, Sinter ducts, Wear protection covers, Liners, Fan blades, Louvers, etc.

Hardness: 58-64 HRc

Download

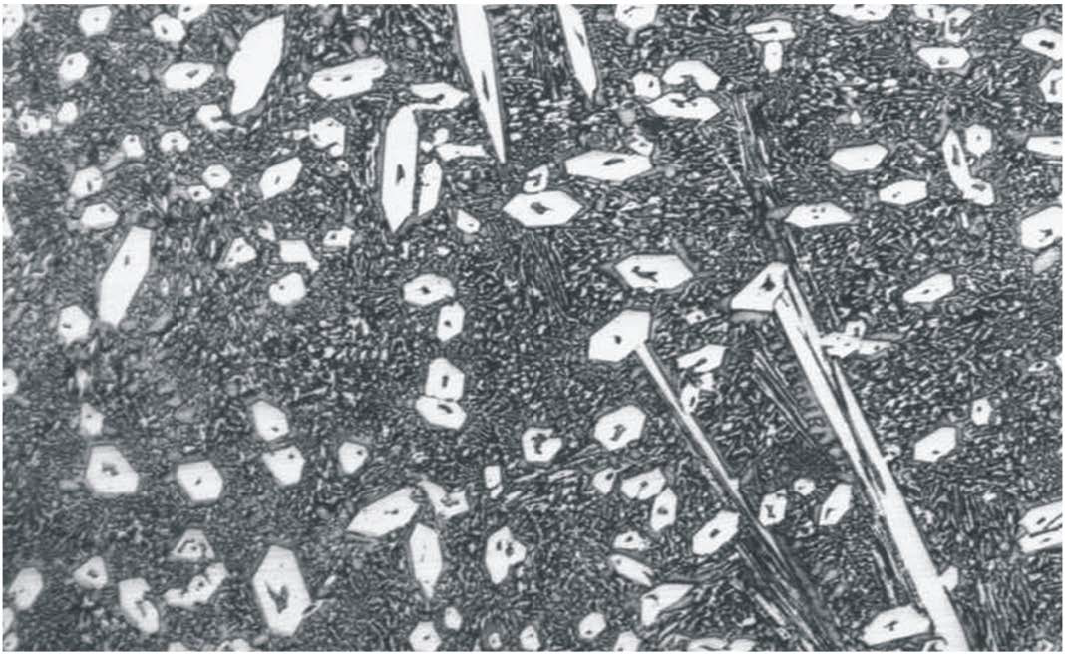

EDP 600 is an iron-chromium-carbon alloy system containing micro-alloying Elements. Designed especially for wear resistance applications upto 350 Deg C.

Typical Applications:

Guide vanes, Fan blades, Louver plates, Nozzle ring segments, Wear

cover, Mill body liners, Coal mil louvers, Mixer blades, Conveyor chutes etc.

Hardness: 60 – 63 HRc

Download

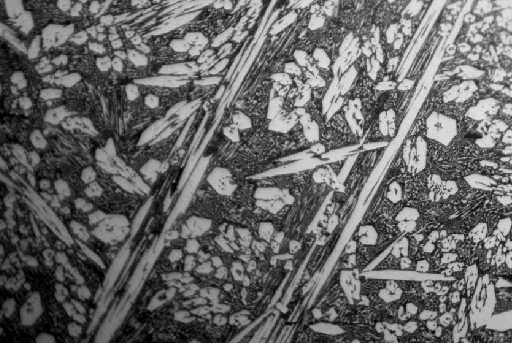

EDP 560 is an iron-chromium-carbon alloy system containing micro-alloying Elements. Designed especially for wear resistance applications upto 350 Deg C.

Typical Applications:

Guide vanes, Fan blades, Louver plates, Nozzle ring segments, Wear cover, Mill body liners, Coal mil louvers, Mixer blades, Conveyor chutes etc.

Hardness: 58 – 64 HRc (depending on thickness)

Download

Wear Plate for Applications involving Severe Abrasion and Moderate Impact

Typical Application

Hardness : 54-58 HRc

Download

Unique composite wear plate for heavy impact combined with pressure and abrasion

Typical Applications:

Secondary crusher discharge chutes, Crusher bodyliners, Material handling impact zone liners, Flapper gates, Impactor liners, Deflector plates, etc.

Hardness: 50 – 60 HRc (First layer)

45 – 55 HRc (Second layer)

Wear plate with improved cutting resistance – both by abrasive wheel and flame which delays cutting time to combat burglar

Typical Application:

Strong rooms, vault doors, safes, safe deposit lockers, security doors etc

Hardness: 54 – 58 HR

Download

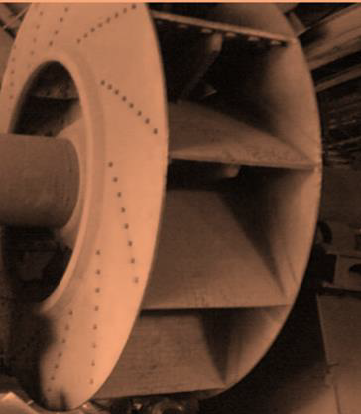

EDP 700 is an iron-based surfacing alloy system containing ultrahard constituents to withstand severe erosive wear. Service temperature of this alloy is restricted to 300 °C.

Typical Applications:

Exhauster fan blades, Guide vanes, Louver plates, ID fans, Classifiers, Separators, etc.

Hardness : 65 – 68 HRc

Download