An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 304 and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 18 Cr/ 8 Ni type stainless steels with normal carbon content.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | Cu |

| 0.04 | 0.75 | 0.50 | 19.00 | 9.50 | 0.02 | 0.03 | 0.02 |

Typical Mechanical Properties:

Tensile Strength : 590 MPa

Elongation (L=4D) : 40%

An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 304, AISI 304L and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 18 Cr/ 8 Ni type stainless steels with normal or extra low carbon content.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | Cu |

| 0.03 | 0.80 | 0.50 | 19.00 | 9.50 | 0.02 | 0.03 | 0.02 |

Typical Mechanical Properties:

Tensile Strength : 550 MPa

Elongation (L=4D) : 40%

An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 316 and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 18 Cr/ 12 Ni/ 2 Mo type stainless steels with normal carbon content.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | Cu | |

| 0.04 | 0.75 | 0.30 | 18.00 | 12.00 | 0.02 | 0.03 | 0.20 |

| Mo |

| 2.20 |

Typical Mechanical Properties:

Tensile Strength : 570 MPa

Elongation (L=4D) : 35%

An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 316, AISI 316L and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 18 Cr/ 12 Ni/ 2 Mo type stainless steels with normal or extra low carbon content.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | Cu | |

| 0.03 | 0.80 | 0.60 | 18.00 | 12.00 | 0.02 | 0.03 | 0.20 |

| Mo |

| 2.30 |

Typical Mechanical Properties:

Tensile Strength : 550 MPa

Elongation (L=4D) : 35%

An Advanced Electrode for highest Quality Welding of Carbon Steels to Molybdenum-Containing Austenitic Stainless Steel of type AISI 316 Mo and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 18 Cr/ 12 Ni/ 2 Mo type stainless steels, and to deposit the ‘barrier’ layer for Molybdenum – containing stainless overlays on carbon steels.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | Cu | |

| 0.04 | 0.80 | 0.30 | 22.5 | 13.00 | 0.02 | 0.03 | 0.20 |

| Mo |

| 2.50 |

Typical Mechanical Properties:

Tensile Strength : 580 MPa

Elongation (L=4D) : 35%

An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 309 and for Welding Carbon Steel to Stainless Steel type AISI 304 and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 25 Cr/ 12 Ni type stainless steels and for welding dissimilar steels such as joining 18 Cr/ 8 Ni type stainless steels for Plain Carbon or Low Alloys Steels. Also useful for depositing ‘barrier’ layer on Plain Carbon Steels prior to overlay with Cr/Ni containing stainless Steels.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | Cu | |

| 0.05 | 0.75 | 0.50 | 23.00 | 13.00 | 0.02 | 0.03 | 0.20 |

An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 309 and for Welding Carbon Steel to Stainless Steel type AISI 304 and Equivalent Grades.

Typical Mechanical Properties:

Tensile Strength : 590 MPa

Elongation (L=4D) : 35%

An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 309L and for Welding Carbon Steel to Stainless Steel type AISI 304 and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 25 Cr/ 12 Ni type stainless steels and for welding dissimilar steels such as joining 18 Cr/ 8 Ni type stainless steels for Plain Carbon or Low Alloys Steels. Also useful for depositing ‘barrier’ layer on Plain Carbon Steels prior to overlay with Cr/Ni containing stainless Steels.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | |

| 0.03 | 0.80 | 0.30 | 23.00 | 13.50 | 0.02 | 0.03 |

| Cu |

| 0.20 |

Typical Mechanical Properties:

Tensile Strength : 580 MPa

Elongation (L=4D) : 35%

An Advanced Electrode for highest Quality Welding of Stainless Steel type AISI 321, AISI 347 and Equivalent Grades.

Principal Applications:

For joining and cladding applications on 18 Cr/ 8 Ni type stainless steels with normal carbon content or those ‘ stabilised’ with Titanium or Coiumbium additions

Typical Weld Metal Chemistry (W%) :

| C | Mn | Si | Cr | Ni | S | P | |

| 0.035 | 0.80 | 0.30 | 19.50 | 9.80 | 0.10 | 0.02 |

| Cb |

| 0.50 |

Typical Mechanical Properties:

Tensile Strength : 580 MPa

Elongation (L=4D) : 35%

ZUPERFAB 310-16 is a Stainless Steel electrode depositing fully austenitic weld metal for SMAW of 25Cr-20Ni type steels

Typical Weld Metal Chemistry (W%) :

| C | Mn | Si | Cr | Ni | S | P | |

| 0.15 | 1.80 | 0.50 | 26.00 | 21.00 | 0.02 | 0.03 |

| Mo |

| 0.2 |

All Weld Mechanical Properties :

Flux-coated Electrode for Welding of Stainless Steel Types AISI 304 & Equivalent Grades

Principal Applications:

For joining and cladding applications on 18 Cr / 8 Ni type stainless steels with normal or high carbon content.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P |

| 0.060 | 0.75 | 0.30 | 19.80 | 10.40 | 0.010 | 0.03 |

Typical Mechanical Properties:

Tensile Strength:600 MPa

Elongation (L=4D): 40%

An Advanced Electrode for highest Quality Welding of Carbon Steels to Molybdenum-Containing Austenitic Stainless Steel of type AISI 316 or Equivalent Grades.

Principal Applications:

For joining Carbon Steels to 18 Cr/ 12 Ni/ 2 Mo type stainless steels, and to deposit the ‘barrier’ layer for Molybdenum – containing stainless overlays on carbon steels.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | P | Cu | Mo |

| 0.04 | 0.80 | 0.30 | 22.50 | 13.00 | 0.02 | 0.03 | 0.20 | 2.50 |

Typical Mechanical Properties:

Tensile Strength:580 MPa

Elongation (L=4D):35%

A Low Heat Input High Performance Stainless Steel Electrode Depositing an Extra Low Carbon 19Cr13Ni & 3Mo Weld Metal

Principal Applications:

For joining and cladding applications on 19-13 type of stainless steel with a maximum resistance to stress, corrosion, cracking, hot cracking and chemical corrosion at high temperature. The weld metal has excellent creep resistance and is of radiographic quality.

Typical All-weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni | S | Mo | P |

| 0.025 | 0.70 | 0.18 | 19.0 | 13.80 | 0.005 | 3.8- | 0.02 |

Typical Mechanical Properties:

Tensile Strength:61 Kg/mm2

Elongation (L=4D):36%

Electrode for Welding of Super Duplex Stainless Steels and Overlaying Of Steels

Principal Applications:

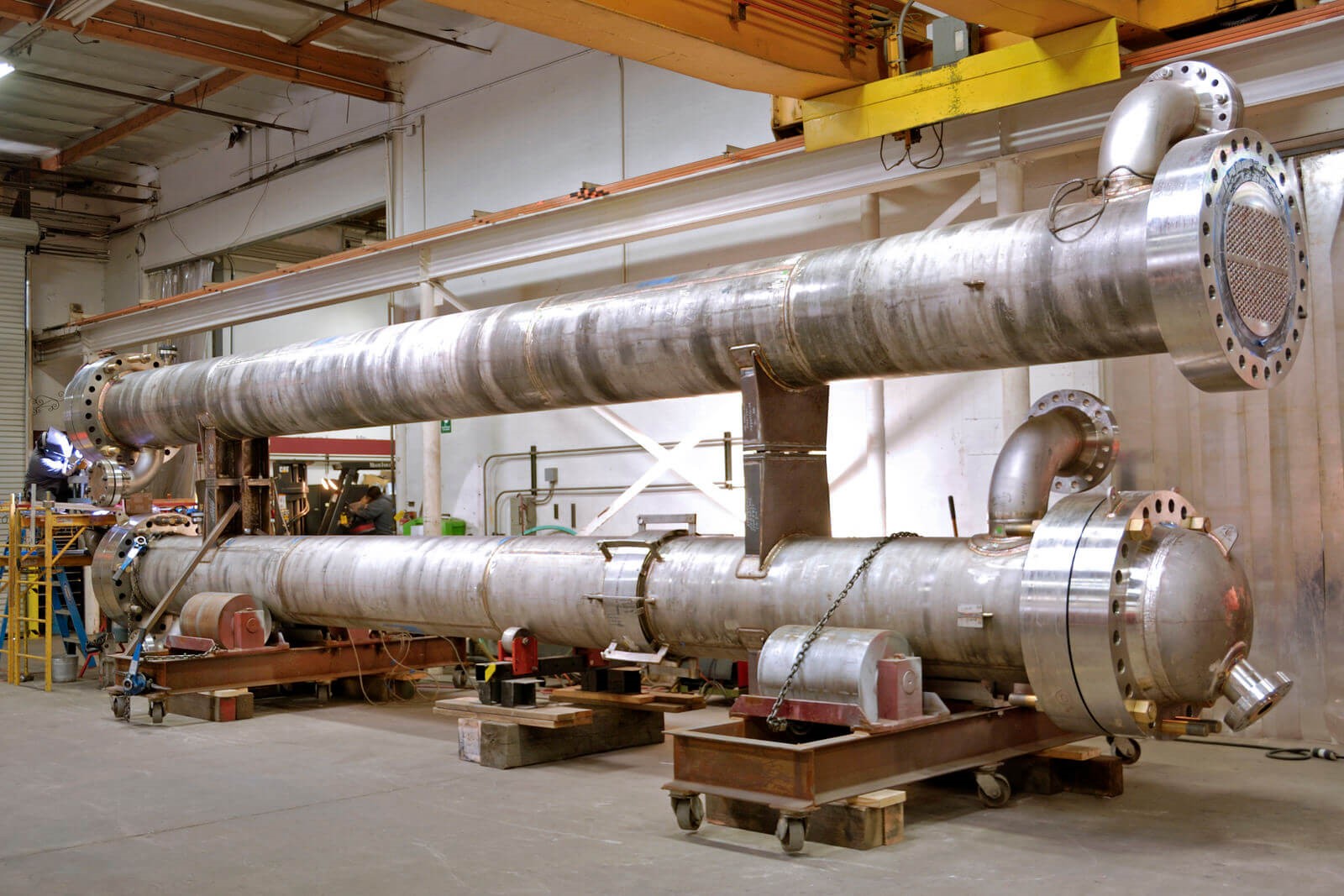

For welding Ferritic-Austenitic Super Duplex Stainless Steel grade (AISI 2207). It can also be used for welding of carbon and low alloy steels to duplex stainless steels and for welding of standard duplex stainless steels (AISI 2205). Typical applications are found in Off-shore engineering, Chemical, Petrochemical, Shipbuilding and Paper and Pulp industries.

Typical Mechanical Properties:

Tensile Strength : 700 MPa

Elongation (L=4D) : 18%

Electrode for Welding of Austenitic Stainless Steels & CrNiMoCu Steels In Severe Corrosive Media.

Principal Applications:

For welding Austenitic stainless steel grades and CrNiMoCu Steels. Typical applications are found in pressure vessels, heat exchangers, paper and allied industries, chemical and pharmaceutical industries. Typically used in environment containing sulfuric and phosphoric acid.

Typical Mechanical Properties:

Tensile Strength : 550 MPa

Elongation (L=4D) : 35%

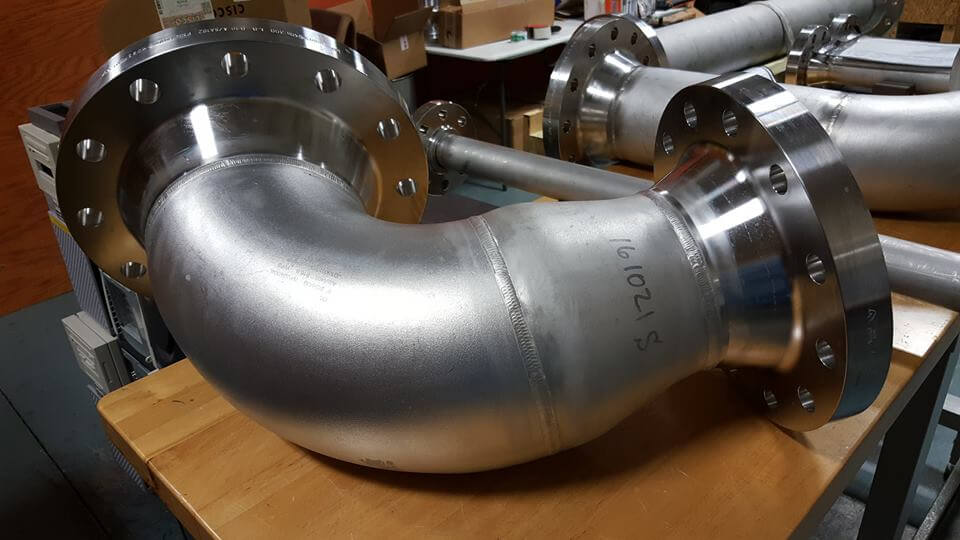

A flux – cored gas shielded wire for welding stainless steels of type 18Cr / 8Ni such as AISI 304/304L Optimum ferrite content of weld deposit assures excellent corrosion resistance without cracking

Typical Application

For joining & cladding applications on 18Cr – 8Ni type of stainless steel with low or normal carbon content.

Typical All Weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni |

| 0.03 | 1.50 | 0.30 | 19.0 | 10.00 |

A flux – cored gas shielded wire for corrosion resistant joining of wide grades of stainless steels to dissimilar steels

Typical Application

For joining Stainless Steels of type 18Cr/8Ni with other dissimilar Steels. Also Suitable as a buffer layer for cladding.

Typical Characteristics:

Typical All Weld Chemistry (Wt%)

| C | Mn | Si | Cr | Ni |

| 0.03 | 1.50 | 0.30 | 24.0 | 13.00 |