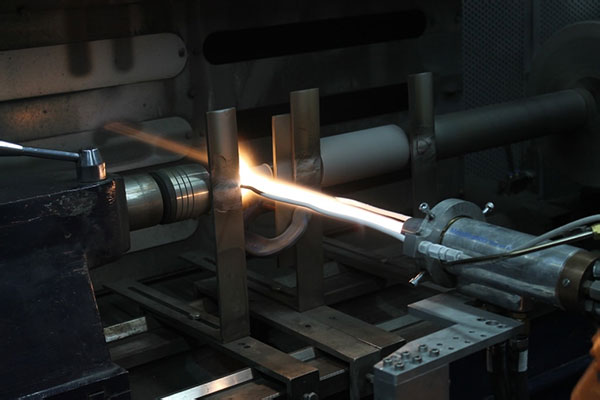

EWAC Reclamation Facility (ERF) specializes in critical turnkey reclamation jobs involving weld surfacing, machining, pre & post weld heat treatment with the latest technologies and up-to-date surfacing materials.

Jobs executed

Customers across major core sector industries spread in the large area provides ample space to undertake a wide range of applications.