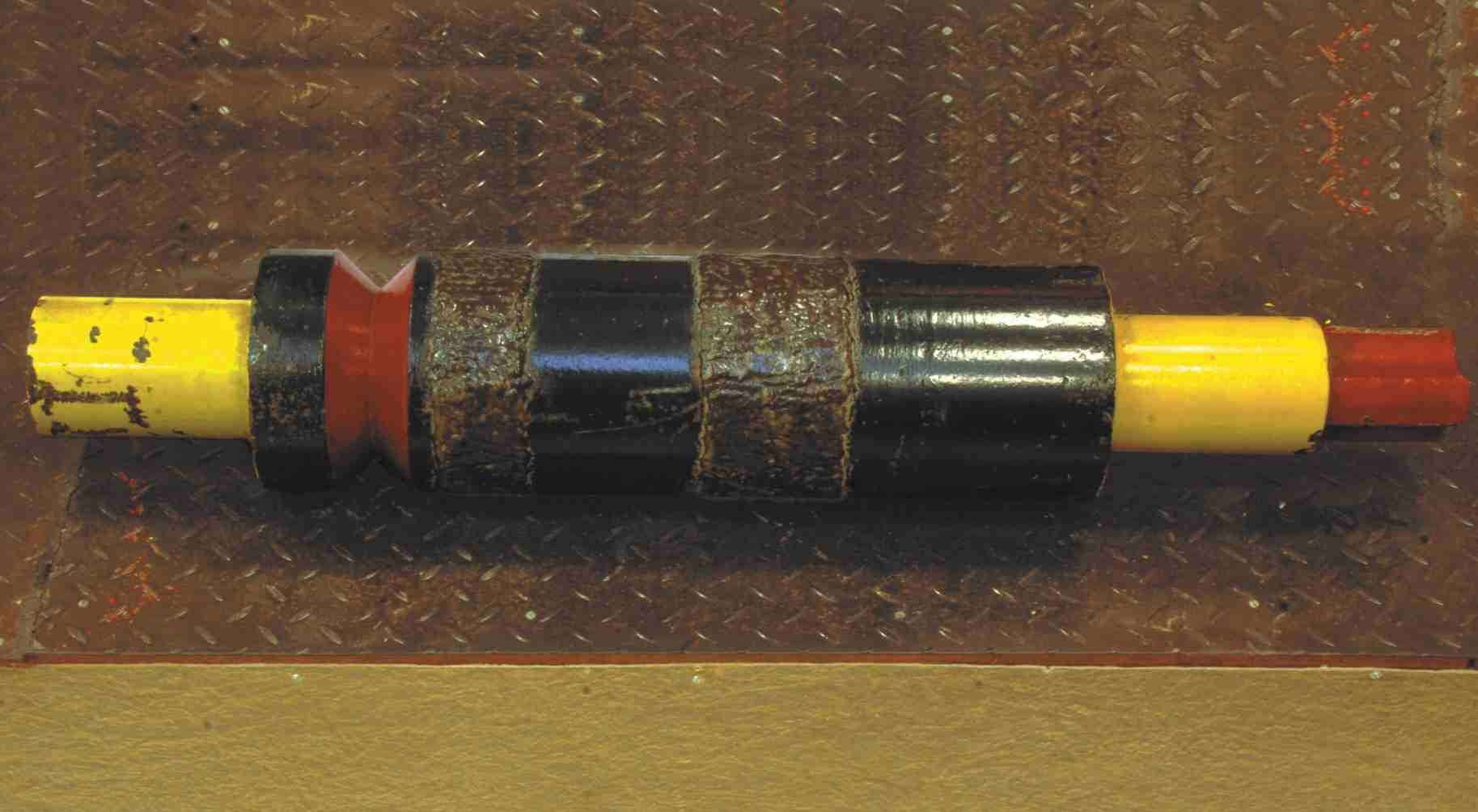

An excellent electrode for gouging and beveling and removable of weld defects for ferrous or non-ferrous metal

Applications:

Special electrode for all position cutting and piercing of all metals

Applications:

All position electrode for welding of low carbon thin sheets, forms and plates

Applications:

Typical Mechanical Properties:

Tensile Strength: : 53 Kg/mm2

(75,000 psi)

Electrode for high strength joining of Mn steel, low alloy steel & medium carbon steel

Applications:

Typical Mechanical Properties:

Tensile Strength: 58 Kg/mm2

(84,000 psi)

Moisture resistant electrode for welding low alloy and high tensile steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 59Kg/mm2

(82,000 psi)

Universal electrode for joining of different steel with high strength heat and corrosion resistance

Applications:

Typical Mechanical Properties:

Tensile Strength: 70 Kg/mm2

(98,000 psi)

A high alloy electrode for welding dissimilar steels and unknown steels – high carbon to all steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 87 Kg/mm2

(1,22,000 psi)

Very low heat input electrode for joining, built-up of dissimilar & difficult to weld steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 87 Kg/mm2

(1,22,000 psi)

Weld metal with high toughness, high strength & ductility for joining dissimilar steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 87 Kg/mm2

(1,22,000 psi)

Special flux coated electrode for joining and repair of heavy and massive sections and dissimilar steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 66 Kg/mm2

(92,000 psi)

Elongation: 30 – 35%

Electrode for joining high alloy steels subjected to thermal cycling and joining without effects of HAZ

Applications:

Typical Mechanical Properties:

Tensile Strength: 66 Kg/mm2

(92,000 psi)

Elongation: 45%

High strength electrode for joining and repair of cast steels and HSLA steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 67 Kg/mm2

(96,000 psi)

Low carbon stainless steel electrode with excellent heat and corrosion resistance for joining and overlay applications

Applications:

Typical Mechanical Properties:

Tensile Strength: 58 Kg/mm2

(82,000 psi)

Excellent electrode for joining wide range of SS and MS base metal for oxidation and heat resistance applications

Applications:

Typical Mechanical Properties:

Tensile Strength: 69 Kg/mm2

(97,000 psi)

Moly-bearing stainless steel electrode with enhanced corrosion resistance both for joining and surfacing

Applications:

Typical Mechanical Properties:

Tensile Strength: 62 Kg/mm2

(87,000 psi)

Stainless steel electrode specially designed for fertilizer industry

Applications:

Typical Mechanical Properties:

Tensile Strength: 56 Kg/mm2

(80,000 psi)

Elongation: 40%

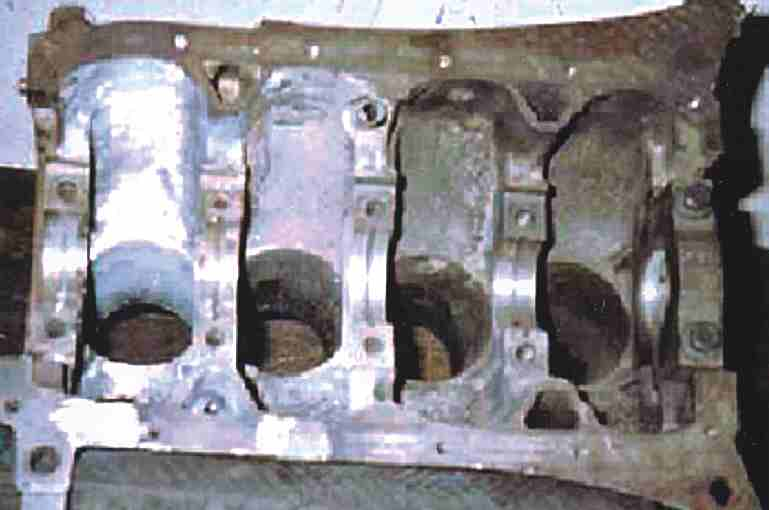

Innovative alloy with strong arc force and cleaning action for contaminated cast irons

Applications:

An excellent electrode for repair of casting defects

Applications:

Typical Mechanical Properties:

Tensile Strength:42 Kg/mm2

(60,000 psi)

Versatile electrode for welding of heavy sections and crack sensitive applications

Applications:

Typical Mechanical Properties:

Tensile Strength: 42 Kg/mm2

(58,000 psi)

A high Ni electrode for repairing thin sections of gray cast iron with excellent machinability

Applications:

Typical Mechanical Properties:

Tensile Strength: 37 Kg/mm2

(52, 000 psi)

A high nickel electrode for repairing gray cast iron and joining casting to steel

Applications:

Typical Mechanical Properties:

Tensile Strength: 37 Kg/mm2

(52,000 psi)

For joining steel to cast Iron & rebuilding of nodular and alloyed cast irons

Applications:

Typical Mechanical Properties:

Tensile Strength: 42 Kg/mm2

(59,000 psi)

Electrode designed with innovative core wire offers good weldability, high tensile strength, ductility and machinability

Applications:

Typical Mechanical Properties:

Tensile Strength: 53 Kg/mm2

(75,000 psi)

Non-ferrous electrode for welding all grades of copper

Applications:

Typical Mechanical Properties:

Tensile Strength:8 – 15 Kg/mm2

Conductivity: 80% IACS

A bronze electrode for welding of bronze, brass, steel, cast iron

Applications:

High strength bronze electrode for welding of bronze, brass, carbon steel & cast iron

Applications:

Typical Mechanical Properties:

Tensile Strength: 35 Kg/mm2

(50,000 psi)

Special aluminium electrode for joining and maintenance welding application

Applications:

Typical Mechanical Properties:

Tensile Strength:25 Kg/mm2

(35,000 psi)

An advanced electrode for applications subjected to abrasive wear

Applications:

Typical Mechanical Properties:

Hardness: 57 – 62 HRc (3 layer)

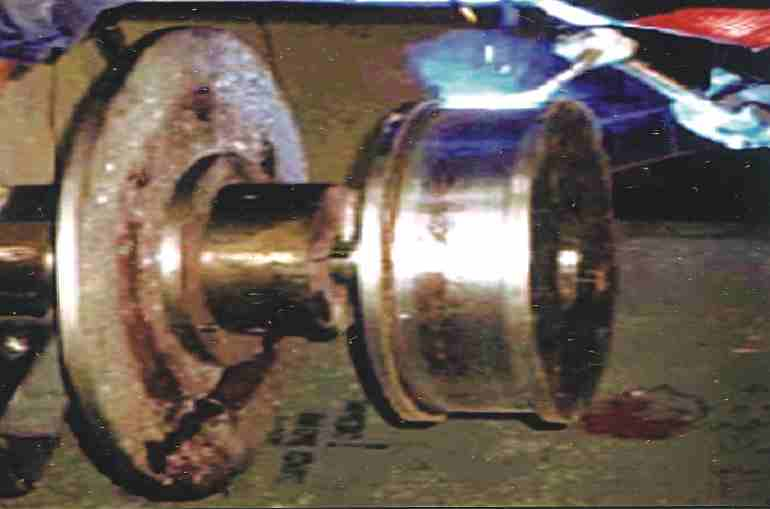

Anti-spalling weld deposit with excellent cushioning, good impact resistance & high compressive strength

Applications:

Typical Mechanical Properties:

Hardness: 28 – 35 HRc (3 layer)

Special electrode for surfacing of cold cutting tool & die application

Applications:

Typical Mechanical Properties:

Hardness: 58 – 65HRc (3 layer)

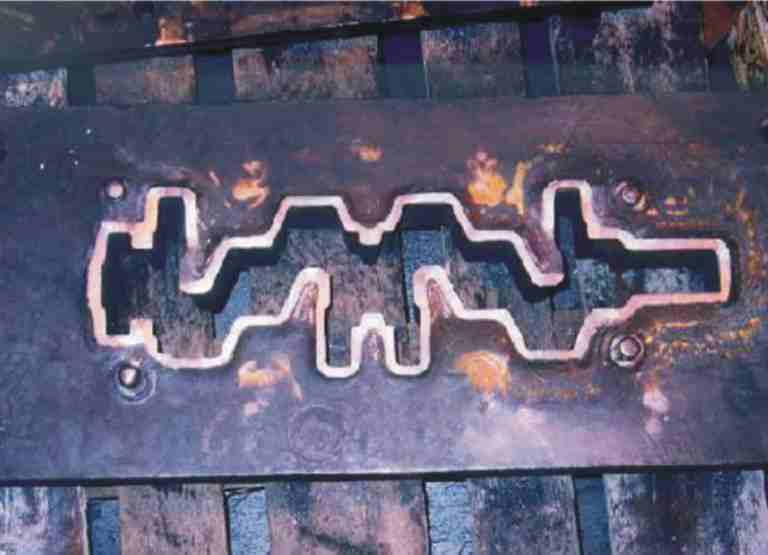

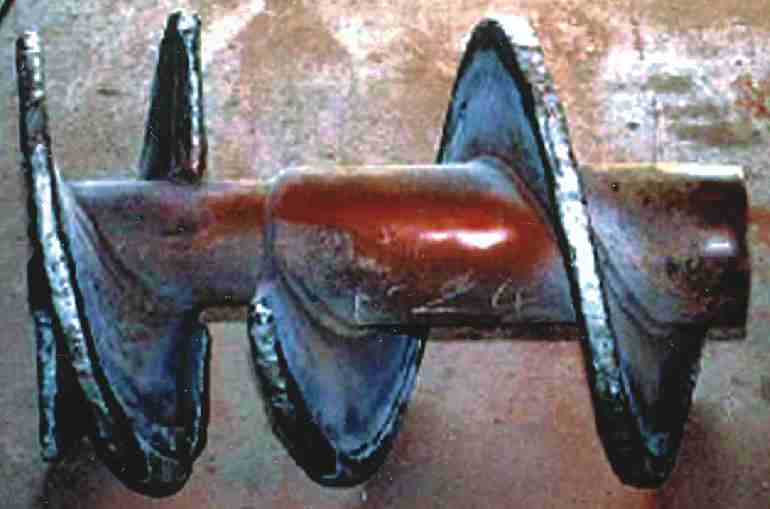

Repair and build-up of drop forging tools and damaged profiles

Applications:

Typical Mechanical Properties:

Hardness: 35 – 45 HRc (3 layer)

High strength electrode for joining and surfacing of dissimilar steels and overlay on low alloy steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 58 Kg/mm2

(82,500 psi)

Heat treatable alloy with good resistance to impact and compressive load upto 500oC

Applications:

Typical Mechanical Properties:

Deposit Hardness:

At 30 Deg C 48 – 52 HRc (3 layer)

At 400 Deg C 42 HRc (3 layer)

High strength electrode for rebuilding of drop-forging dies

Applications:

Typical Mechanical Properties:

Hardness:

As welded 35 – 45 Rockwell C (3 layer)

After Tempering:

35 – 42 Rockwell C (3 layer)

High strength electrode for rebuilding of press-forging dies and tools

Applications:

Typical Mechanical Properties:

Hardness:

38 – 44 HRc (As welded)

36 – 42 HRc (After Tempering)

A new generation electrode for surfacing of Cr-Mo alloyed cast iron dies

Applications:

Typical Mechanical Properties:

Hardness:

As deposited 42 – 48 HRc (3 layer)

Electrode with excellent shearing properties for automotive die applications

Applications:

Typical Mechanical Properties:

Hardness:

As deposited 54 – 58 HRc (3 layer)

High Hardness Tubular Electrode for Severe Abrasion Resistance

Applications:

Typical Mechanical Properties:

Hardness: 60 – 65 HRc (2 layer)

Unique tubular electrode with high abrasion resistance property

Typical Applications:

Typical Mechanical Properties:

Hardness: 55 – 62 HRc (2 layer)

Tubular Electrode with High Temperature Tribological Properties

Applications:

High temperature wear resistant coatings on all type of carbon steels and stainless steels.

Typical Mechanical Properties:

Hardness: 65 – 70 HRc (2 layer)

(on MS); 58 – 63 HRc (on SS 304)

Tungsten carbide based tubular electrode for severe abrasive wear

Applications:

Typical Mechanical Properties:

Hardness: 60 – 65 HRc (2 layer)

Special electrode for severe abrasive wear at elevated temperature

Applications:

Typical Mechanical Properties:

Hardness: 60 – 68 HRc (2 layer)

An advanced wear facing electrode designed for severe abrasion applications under pressure and moderate impact

Applications:

Typical Mechanical Properties:

Hardness: 60 – 65 HRc (2 layer)

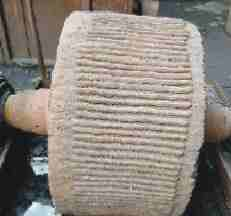

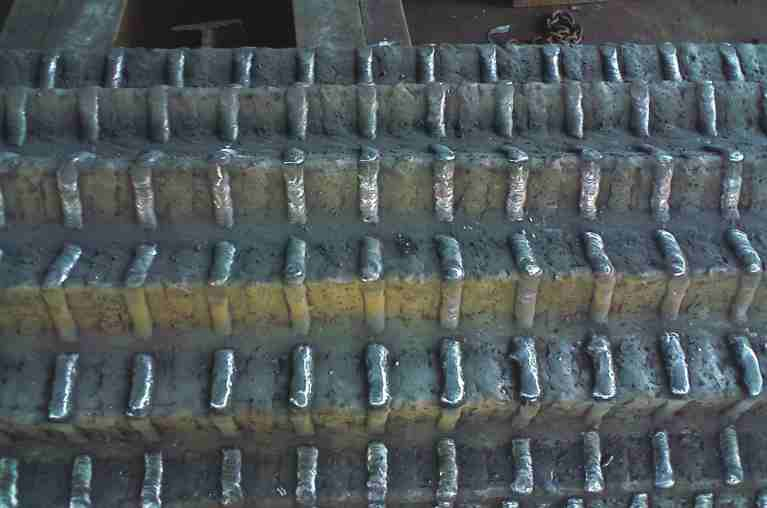

Special electrode for improving gripping & wear protection of sugarcane crusher roll teeth

Applications:

Typical Mechanical Properties:

Hardness: 50 – 60 HRc

A wear resistant hard surfacing ‘paint-on-paste’ for fine particle abrasion & erosion

Applications:

Typical Mechanical Properties:

Coverage: 300 cc/kg of paste (Avg. coating thickness = 1.5mm) Hardness: 68 – 72 HRc

A versatile electrode with excellent resistance to impact with work hardening capability

Applications:

A high alloy electrode for wear protective coating & high strength joining

Applications:

For joining: Under carriage parts, sprockets, ripper shanks

For Build-up: Gear teeth, impactors, sprockets, trencher teeth, bucket teeth, hammers, augers, under carriage components, scrapper blades, crusher jaws

Typical Mechanical Properties:

Hardness:

As deposited 80-95 HRb Work hardened 28-35 HRc

Tensile Strength: 64 Kg/mm2

(90,000 psi)

Wear facing alloy for protective coating, repair and joining application on 13% Cr-steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 107 kg/mm2

(1,50,000 psi)

Hardness: 33 – 40 HRc (3 layer)

An unique electrode for applications subjected to abrasion, erosion, corrosion combined with impact

Applications:

Typical Mechanical Properties:

Hardness: 54 – 62 HRc (3 layer)

An advanced fastest work hardenable alloy with superior anti-impact property coupled with pressure and abrasion

Applications:

Typical Mechanical Properties:

Hardness:

As deposited 20 – 24 HRc

Work hardened 35 – 48 HRc

Tensile Strength: 87 Kg/mm2

Download

A unique titanium carbide alloy system for wear-facing against severe impact & abrasion

Applications:

Typical Mechanical Properties:

Hardness: 52 – 60 HRc

Very high abrasion resistant alloy with extra high deposition rates

Applications:

Typical Mechanical Properties:

Hardness: 62 – 68 HRc (2 layer)

Weld metal with outstanding abrasive wear resistance even at elevated temperature

Applications:

Typical Mechanical Properties:

Hardness: 63 – 69 HRc (2 layer)

A high alloy electrode for joining and overlaying of nickel based alloys

Applications:

Typical Mechanical Properties:

Tensile Strength: 75 Kg/mm2

(1,05,000 psi)

Cobalt base alloy with excellent wear resistance at elevated temperatures

Applications:

Typical Mechanical Properties:

Hardness: 32 – 47 HRc (3 layer)

Cobalt base alloy with superior wear properties for critical surfacing and repair applications at high temperatures

Applications:

Typical Mechanical Properties:

Hardness: 25 – 38 HRc ( 3 layer)

Cobalt based alloy with excellent resistance to heat, impact and abrasion

Applications:

Typical Mechanical Properties:

Hardness: 40 – 52 HRc (3 layer)

Scientifically engineered electrode based on Nano Technology, that exhibits extraordinary wear resistance given at elevated temperatures

Applications:

Typical Mechanical Properties:

Hardness: 67 – 71 HRc

Cobalt based Surfacing Alloy for Hot Abrasion & Corrosion Resistance

Applications:

Typical Mechanical Properties:

Hardness: 35 – 45 HRc

Work hardening Cobalt based Surfacing alloy with Hot Impact Resistance & Edge Retention Properties

Applications:

Typical Mechanical Properties:

Hardness: 28 – 35 HRc (As welded)

45 – 50 HRc (Work hardened)

New Generation Electrode for Surfacing and Build-up of Dies & Tools

Typical Applications:

A versatile electrode for superior abrasion resistance

Applications:

Typical Mechanical Properties:

Hardness: 58-70 HRc (3 layer)

Open arc self shielded wire for crack – free joining and build up applications

Applications:

Typical Mechanical Properties:

Tensiles Strength: 49 Kg/mm2

(70,000 psi)

Open arc self-shielded flux cored wire for high strength similar and dissimilar joining of low, medium carbon and low alloy steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 65 Kg/mm2

(92,000 psi)

Open arc self-shielded flux cored continuous wire for impact and compressive load applications

Applications :

Typical Mechanical Properties:

Hardness: 25 to 35 HRc (3 layer)

Open arc self-shielded flux cored wire with excellent resistance to impact and work hardening capability

Applications:

Typical Mechanical Properties:

Hardness:

As Deposited: 90 HRb (3 layer)

Work Hardened: 42 HRc (3 layer)

Open arc self shielded continuous wire designed to resist impact, galling and pressure

Applications:

Typical Mechanical Properties:

Tensile Strength: 55 Kg/mm2

(78,000 psi)

Open arc self-shield metal wed wire for hardfacing applications in construction and mining industries

Applications:

Typical Mechanical Properties:

Hardness: 50 – 58 HRc (3 layer)

Open arc self-shielded flux cored wire for severe wear by fine particle abrasion or erosion under moderate impact

Applications:

For wear protection of steel components in brick and tile, quarry and dredging industry :

Typical Mechanical Properties:

Hardness: 62 – 67 HRc (2 layer)

Open arc self-shielded Alloy wire containing niobium carbides for severe abrasive and erosive wear at elevated temperatures

Applications:

Typical Mechanical Properties:

Hardness: 60 – 68 HRc

Open arc self-shield flux cored wire with outstanding abrasive wear resistance even at elevated temperatures

Applications:

Typical Mechanical Properties:

Hardness: 58 – 64 HRc (3 layer)

Open arc self-shielded flux cored wire for wear-facing against abrasion and impact

Applications:

Typical Mechanical Properties:

Hardness: 52 – 58 HRc

Open arc self shielded continuous wire designed to withstand abrasion and moderate impact

Applications:

Typical Mechanical Properties:

Hardness: 50 – 60 HRc (3 layer)

Open arc self-shielded continuous wire for anti-spalling deposit with excellent cushioning, good impact resistance and high compressive strength

Applications:

Typical Mechanical Properties:

Hardness: 25 – 35 HRc (3 layer)

Open arc self-shield flux cored wire for joining and build up applications

Applications:

Typical Mechanical Properties:

Tensile Strength: 49 Kg/mm2

(69,000 psi)

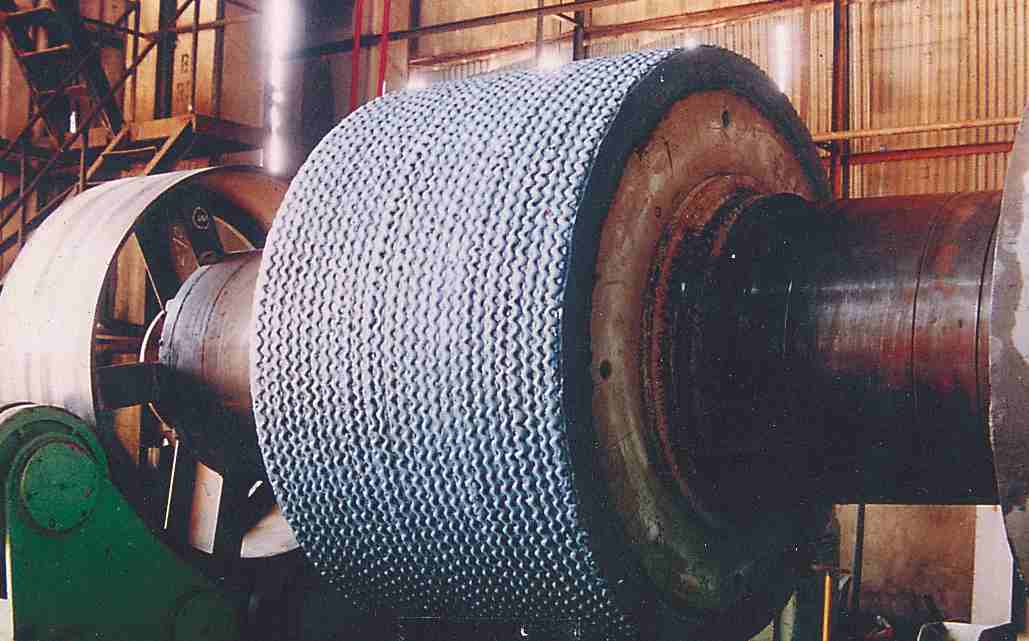

Open arc self-shield continuous wire for build-up of table and roller liners

Applications:

Typical Mechanical Properties:

Hardness: 56 – 62 HRc

Open arc self-shield flux cored wire with excellent resistance to serve abrasion and erosion at elevated temperature

Applications:

Typical Mechanical Properties:

Hardness: 60 – 68 HRc

(3 layer hardness)

High alloyed flux core wire for welding dissimilar steels and unknown steels

Applications:

Typical Mechanical Properties:

Tensile Strength: 78 Kg/mm2

(1,10,000 psi)

Open arc self-shielded flux cored wire for joining and build up applications

Applications:

Typical Mechanical Properties:

Hardness: 85 – 90 HRb

Tensile Strength: 52 Kg/mm2

(73,000 psi)

Open arc self-shielded continuous wire having resistance to high impact and compression

Applications:

Typical Mechanical Properties:

Hardness (As Deposited) : 16 – 25 HRc (3 layer)

Work Hardened : 32 – 47 HRc (3 layer)

Open arc self-shielded continuous wire with high resistance to impact and pressure

Applications:

Typical Mechanical Properties:

Hardness:

As Deposited: 85 – 95 HRb (3 layer)

Work Hardened: 25 – 32 HRb (3 layer)

Open arc self-shielded continuous wire with outstanding abrasive wear resistance at elevated temperature

Applications:

Typical Mechanical Properties:

Hardness : 58 – 65 HRc (2 layer)

Open arc self-shielded flux cored wire with good resistance to impact and compressive load upto 500 deg C

Typical Mechanical Properties:

Hardness: 52 – 58

HRc (3 layer)

Open arc self-shielded flux cored wire with superior resistance to 2-body abrasion and low-to-medium impact

Applications:

For wear preventive protection of parts in

Typical Mechanical Properties:

Hardness: 50 – 58 HRc

(3 layer )

Open arc self-shielded flux cored wire with excellent resistance to 3-body abrasion and moderate-to-heavy impact

Applications:

For wear protective coatings of

Typical Mechanical Properties:

Hardness: 45 – 55 HRc (2 layer)

Open arc self-shielded flux cored wire for joining, fillet welding and build-up applications

Applications:

Typical Mechanical Properties:

Hardness: 20 – 32 HRc

Tensile Strength: 58 Kg/mm2 (82,000 psi)

Download

FCAW Wire for Drop Forging Tools & Dies

Applications:

Typical Mechanical Properties:

Hardness: 40 – 46 HRc (as welded)

38 – 45 HRc (after tempering at 550-600 °C for 1hr per inch job thickness)

Open arc self-shield continuous wire for build-up of table and roller liners

Applications:

Hardness: 56 – 62 HRc

Download

Flux coated brazing alloy suitable for joining of dissimilar steel to Cu alloy including Ni enhanced high strength bronzes

Applications:

Typical Mechanical Properties:

Bonding Temperature: 875 Deg C

Tensile Shear Strength: 50 Kg/mm2

(1,05,000 psi)

Low temperature silver brazing alloy for high strength joining of dissimilar metals

Applications:

Typical Mechanical Properties:

Rod: 1.6, 2.0, 3.15mm

Shim: 25mm x 0.075 mm

Bonding Temperature: 660 Deg C

Tensile Strength: 45 Kg/mm2(63,000 psi)

Torch brazing rod for self-fluxing copper-to-copper joints

Applications:

Typical Mechanical Properties:

Bonding Temperature : 650 Deg C

Tensile Strength : 37 Kg/mm2 (52,000 psi)

High silver brazing alloy with excellent fluidity for brazing narrow clearance joints

Applications:

Typical Mechanical Properties:

Bonding Temperature : 600 Deg C

Tensile Strength: 65 Kg/mm2 (92,000 psi)

An advanced brazing rod for high strength joining of aluminium parts

Applications:

Typical Mechanical Properties:

Bonding Temperature: 570 Deg C

Tensile Strength: 25 Kg/mm2 (35,000 psi)

Flux coated brazing alloy for built up & overlay application on all ferrous and non-ferrous alloys

Applications:

Typical Mechanical Properties:

Hardness: 95 HRb

Bonding Temperature: 875 Deg C

Tensile Strength: 62 Kg/mm2 (87,000 psi)

Composite gas brazing filler rod with hard carbides embedded in tough matrix

Applications:

Typical Mechanical Properties:

Hardness: Matrix – 210 BHN,

Carbides – 1250 HV (min)

Paint-on solder paste for soldering of dissimilar metals except Al and Mg

Applications:

Typical Mechanical Properties:

Bonding Temperature: 190 Deg C

Tensile Strength: 4 Kg/mm2 (7200 psi)

A solder alloy with excellent corrosion resistance suitable for SS, brass, bronze, Ni alloys and carbon steels parts

Applications:

Typical Mechanical Properties:

Bonding Temperature: 225 Deg C

Note: Also available in paste

form as EWACSTIK 114 P

Tensile Strength: 11 Kg/mm2 (16,000 psi)

Nickel – base alloy with excellent wear properties

Applications:

Typical Mechanical Properties:

Hardness: 55 – 62 HRc Max.

Thickness: 1.5 to 2 mm

Tungsten carbide reinforced Nickel – base alloy with exceptional resistance to abrasion and erosion

Applications:

Typical Mechanical Properties:

Hardness: 57 – 64 HR Max.

Thickness: 1.5 mm

Ni – B – Si system offers combination of wear, toughness, hardness and machinability

Applications:

Typical Mechanical Properties:

Hardness: 36 – 42 HRc

Nickel – base alloy ideal for filling, sealing, cladding & joining cast iron to steel

Applications:

Typical Mechanical Properties:

Hardness:80 – 100 HRb

Nickel – base alloy for faster deposition for joining, cladding and sealing

Applications:

Typical Mechanical Properties:

Hardness: 80 – 100 HRb

Finest microflo alloy for high temperature service

Applications:

Typical Mechanical Properties:

Hardness: 45 – 50 HRc

Emergency repair applications

Applications:

General repair and build – up application

Applications:

Protection against corrosive wear

Applications:

Protection against abrasive wear

Applications:

Protection against impact and cavitation

Applications:

Protection of surfaces against general wear upto 1750C

Applications:

Protection of large surfaces against corrosion and wear

Applications: